BSP Thread Meaning

BSP (British Standard Pipe) thread, or British Pipe Thread, is a pipe thread standard developed by the British Standards Institution (BSI) and is widely used in hydraulics, pneumatics, piping connections, and other fields.

BSP thread is divided into two main types:

BSPP (G thread): parallel thread (non-tapered), relying on sealing washers or O-rings to achieve sealing.

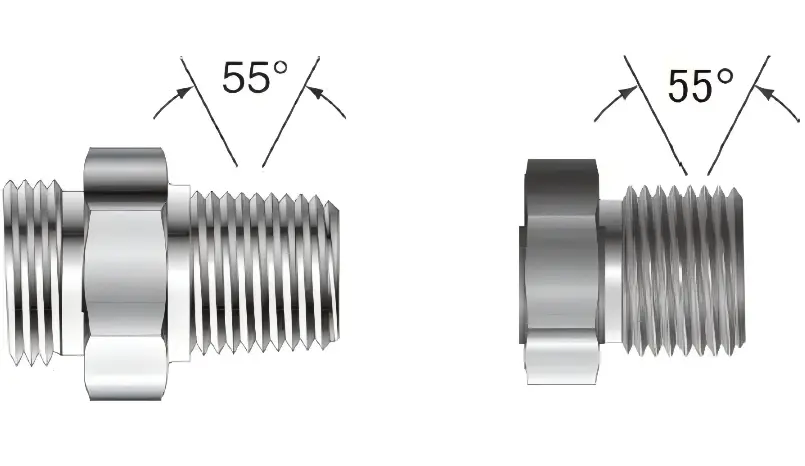

BSPT (R thread): conical thread (55° tooth angle), sealing is achieved by the taper of the thread itself.

BSP thread characteristics

Tooth angle: 55°

Thread type: parallel (BSPP/G) or tapered (BSPT/R)

Measuring reference: in inches (e.g. 1/8“, 1/4”, 1/2”, etc.)

Sealing method:

BSPP (G thread): with gasket or sealant required

BSPT (R thread): self-sealing by thread taper

BSP Thread Chart

| G / R size | Thread density (TPI) | Thread pitch | Major diameter | Minor diameter | Gauge length | Tapping drill | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| R 95% | G 80% | |||||||||

| (in) | (in−1) | (mm) | (in) | (mm) | (in) | (mm) | (in) | (mm) | (mm) | (mm) |

| 1⁄16 | 28 | 0.907 | 0.3041 | 7.723 | 0.2583 | 6.561 | 5⁄32 | 4.0 | 6.6 | 6.8 |

| 1⁄8 | 28 | 0.907 | 0.3830 | 9.728 | 0.3372 | 8.566 | 5⁄32 | 4.0 | 8.6 | 8.8 |

| 1⁄4 | 19 | 1.337 | 0.5180 | 13.157 | 0.4506 | 11.445 | 0.2367 | 6.0 | 11.5 | 11.8 |

| 3⁄8 | 19 | 1.337 | 0.6560 | 16.662 | 0.5886 | 14.950 | 1⁄4 | 6.4 | 15.0 | 15.3 |

| 1⁄2 | 14 | 1.814 | 0.8250 | 20.955 | 0.7335 | 18.631 | 0.3214 | 8.2 | 18.7 | 19.1 |

| 5⁄8 | 14 | 1.814 | 0.9020 | 22.911 | 0.8105 | 20.587 | 0.3214 | 8.2 | 20.7 | 21.1 |

| 3⁄4 | 14 | 1.814 | 1.0410 | 26.441 | 0.9495 | 24.117 | 3⁄8 | 9.5 | 24.2 | 24.6 |

| 7⁄8 | 14 | 1.814 | 1.1890 | 30.201 | 1.0975 | 27.877 | 3⁄8 | 9.5 | 28.0 | 28.3 |

| 1 | 11 | 2.309 | 1.3090 | 33.249 | 1.1926 | 30.291 | 0.4091 | 10.4 | 30.4 | 30.9 |

| 11⁄8 | 11 | 2.309 | 1.4920 | 37.897 | 1.3756 | 34.939 | 0.4091 | 10.4 | 35.1 | 35.5 |

| 11⁄4 | 11 | 2.309 | 1.6500 | 41.910 | 1.5335 | 38.952 | 1⁄2 | 12.7 | 39.1 | 39.5 |

| 13⁄8 | 11 | 2.309 | 1.7450 | 44.323 | 1.6285 | 41.365 | 1⁄2 | 12.7 | 41.5 | 42.0 |

| 11⁄2 | 11 | 2.309 | 1.8820 | 47.803 | 1.7656 | 44.845 | 1⁄2 | 12.7 | 45.0 | 45.4 |

| 15⁄8 | 11 | 2.309 | 2.0820 | 52.883 | 1.9656 | 49.926 | 5⁄8 | 15.9 | 50.1 | 50.5 |

| 13⁄4 | 11 | 2.309 | 2.1160 | 53.746 | 1.9995 | 50.788 | 5⁄8 | 15.9 | 50.9 | 51.4 |

| 17⁄8 | 11 | 2.309 | 2.2440 | 56.998 | 2.1276 | 54.041 | 5⁄8 | 15.9 | 54.2 | 54.6 |

| 2 | 11 | 2.309 | 2.3470 | 59.614 | 2.2306 | 56.656 | 5⁄8 | 15.9 | 56.8 | 57.2 |

| 21⁄4 | 11 | 2.309 | 2.5870 | 65.710 | 2.4706 | 62.752 | 11⁄16 | 17.5 | 62.9 | 63.3 |

| 21⁄2 | 11 | 2.309 | 2.9600 | 75.184 | 2.8435 | 72.226 | 11⁄16 | 17.5 | 72.4 | 72.8 |

| 23⁄4 | 11 | 2.309 | 3.2100 | 81.534 | 3.0935 | 78.576 | 13⁄16 | 20.6 | 78.7 | 79.2 |

| 3 | 11 | 2.309 | 3.4600 | 87.884 | 3.3435 | 84.926 | 13⁄16 | 20.6 | 85.1 | 85.5 |

| 31⁄4 | 11 | 2.309 | 3.7000 | 93.980 | 3.5835 | 91.022 | 7⁄8 | 22.2 | 91.2 | 91.6 |

| 31⁄2 | 11 | 2.309 | 3.9500 | 100.330 | 3.8335 | 97.372 | 7⁄8 | 22.2 | 97.5 | 98.0 |

| 33⁄4 | 11 | 2.309 | 4.2000 | 106.680 | 4.0835 | 103.722 | 7⁄8 | 22.2 | 103.9 | 104.3 |

| 4 | 11 | 2.309 | 4.4500 | 113.030 | 4.3335 | 110.072 | 1 | 25.4 | 110.2 | 110.7 |

| 41⁄2 | 11 | 2.309 | 4.9500 | 125.730 | 4.8335 | 122.772 | 1 | 25.4 | 122.9 | 123.4 |

| 5 | 11 | 2.309 | 5.4500 | 138.430 | 5.3335 | 135.472 | 11⁄8 | 28.6 | 135.6 | 136.1 |

| 51⁄2 | 11 | 2.309 | 5.9500 | 151.130 | 5.8335 | 148.172 | 11⁄8 | 28.6 | 148.3 | 148.8 |

| 6 | 11 | 2.309 | 6.4500 | 163.830 | 6.3335 | 160.872 | 11⁄8 | 28.6 | 161.0 | 161.5 |

| 7 | 10 | 2.540 | 7.4500 | 189.230 | 7.3220 | 185.979 | 13⁄8 | 34.9 | 186.1 | 186.6 |

| 8 | 10 | 2.540 | 8.4500 | 214.630 | 8.3220 | 211.379 | 11⁄2 | 38.1 | 211.5 | 212.0 |

| 9 | 10 | 2.540 | 9.4500 | 240.030 | 9.3220 | 236.779 | 11⁄2 | 38.1 | 236.9 | 237.4 |

| 10 | 10 | 2.540 | 10.4500 | 265.430 | 10.3220 | 262.179 | 15⁄8 | 41.3 | 262.3 | 262.8 |

| 11 | 8 | 3.175 | 11.4500 | 290.830 | 11.2900 | 286.766 | 15⁄8 | 41.3 | 287.0 | 287.6 |

| 12 | 8 | 3.175 | 12.4500 | 316.230 | 12.2900 | 312.166 | 15⁄8 | 41.3 | 312.4 | 313.0 |

| 13 | 8 | 3.175 | 13.6800 | 347.472 | 13.5200 | 343.408 | 15⁄8 | 41.3 | 343.6 | 344.2 |

| 14 | 8 | 3.175 | 14.6800 | 372.872 | 14.5200 | 368.808 | 13⁄4 | 44.5 | 369.0 | 369.6 |

| 15 | 8 | 3.175 | 15.6800 | 398.272 | 15.5200 | 394.208 | 13⁄4 | 44.5 | 394.4 | 395.0 |

| 16 | 8 | 3.175 | 16.6800 | 423.672 | 16.5200 | 419.608 | 17⁄8 | 47.6 | 419.8 | 420.4 |

| 17 | 8 | 3.175 | 17.6800 | 449.072 | 17.5200 | 445.008 | 2 | 50.8 | 445.2 | 445.8 |

| 18 | 8 | 3.175 | 18.6800 | 474.472 | 18.5200 | 470.408 | 2 | 50.8 | 470.6 | 471.2 |

Quote from:https://en.wikipedia.org/wiki/British_Standard_Pipe

BSP threads are used in a wide range of applications

BSP threads are widely used in:

Hydraulic systems (e.g. oil pipes, cylinder joints)

Pneumatic equipment (e.g. air compressors, air tools)

Plumbing and HVAC systems (e.g. imperial pipe connections)

Industrial equipment (e.g. pressure gauges, valves, pump bodies)

BSP thread compatibility

Incompatible with NPT threads: BSP (55° tooth angle) and NPT (60° tooth angle) have different tooth profiles and forced mixing can lead to leakage or damage to the threads.

BSPP and BSPT compatibility:

BSPP (G thread) can be used with BSPP of the same size, but additional sealing measures are required.

BSPT (R thread) is usually used with BSPP (Rp female thread) to form a seal.

Sealing Mechanism for BSP Threads

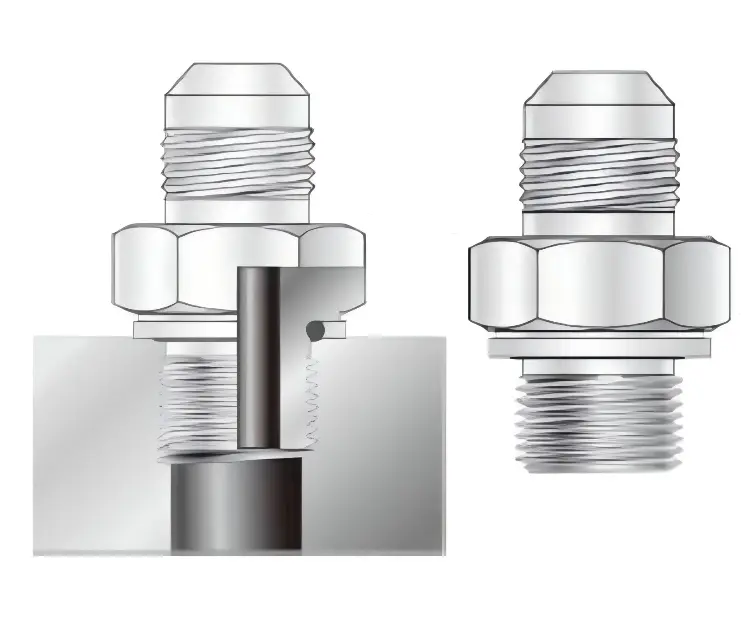

BSPP (G thread):

Relies on end face sealing (e.g., gaskets, O-rings, or sealant).

Commonly used in low pressure systems.

BSPT (R thread):

Self-sealing by thread taper (similar to NPT threads).

Suitable for medium and high pressure systems.

Installation of BSP threads

- BSPP (G thread) installation:

Wrap threads with sealant or PTFE tape.

Install gasket or O-ring to ensure end seal.

Tighten with a wrench, but avoid over-locking to cause deformation. - BSPT (R thread) installation:

Use PTFE tape or thread sealant.

Screw in manually and then tighten 1~2 turns with a wrench to ensure taper sealing.

Advantages and Disadvantages Analysis of BSP Thread

Advantages of BSP threads

High degree of standardization: Widely used in Europe and Asia.

Reliable sealing (BSPT): tapered threads are self-sealing.

High pressure resistance (BSPT is suitable for medium and high pressure systems).

Disadvantages of BSP threads

Incompatible with NPT: limited use in the North American market.

BSPP requires additional sealing: parallel threads rely on gaskets or glue, which may increase the risk of leakage.

Higher installation requirements: over-tightening may lead to thread damage.

Differences between BSP, NPT and Metric Threads

| Features | BSP Threads (G/R) | NPT Threads | Metric Threads (e.g., M Threads) |

| Thread Angle | 55° | 60° | 60° (e.g. M threads) |

| Thread Type | Parallel (G) or Tapered (R) | Tapered | Parallel or Tapered |

| Seal Type | Gasket | Taper Seal | Gasket/O-Ring |

| Units | Inch | Inches | Millimeters (e.g. M10 x 1.5 |

| Main Markets | Europe, Asia | North America | Global (ISO Standard) |

Common problems with BSP threads in use

Leakage Problems:

BSPP not gasketed or taped.

BSPT is not properly tightened or threads are damaged. 2.

Thread confusion:

Mistakenly mixing BSP with NPT results in seal failure. 3.

Overtightening:

Resulting in deformed or cracked threads.

Corrosion Problems:

Carbon steel BSP threads are susceptible to rusting in wet environments.

Size mismatch:

There may be minor differences in BSP standards in different countries (e.g. Japanese JIS vs. British BS).

Conclusion:

BSP threads are an important standard for imperial pipe connections for hydraulic, pneumatic and industrial piping systems. Correct selection of BSPP or BSPT, use of proper sealing methods, and avoiding confusion with NPT will ensure reliability and durability. When installing, make sure to follow the standard operation to prevent leakage or thread damage, if you have more related questions about BSP thread, please contact our engineer, who will offer you free service.