BSPT Meaning

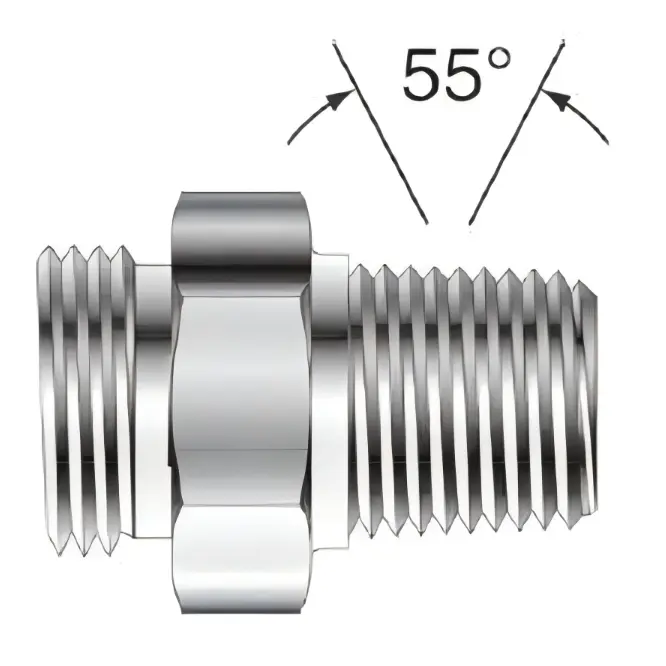

BSPT Thread (British Standard Pipe Taper Thread)

Full name: British Standard Pipe Taper thread

Standard: Follows BS 21/ISO 7-1 standard.

Characteristics: with a 1:16 taper (i.e., 1/16 inch diameter change per inch of length), the thread angle is 55 °.

Sealing mechanism: metal-to-metal sealing is achieved by the taper of the thread itself, usually with a sealant or PTFE tape.

BSPP Meaning

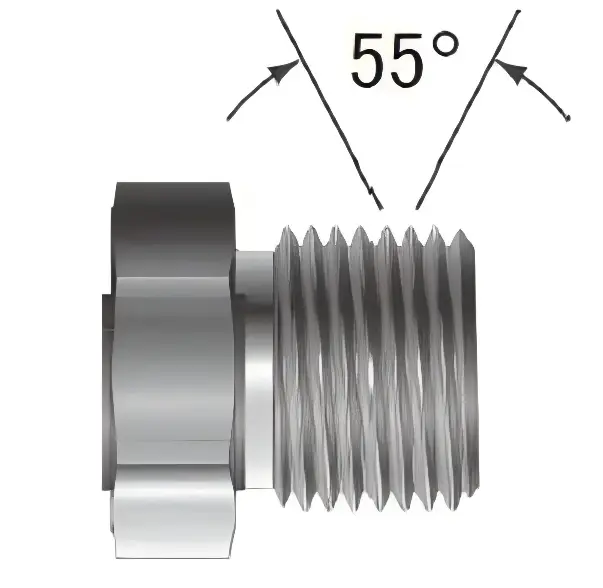

BSPP Thread (British Standard Parallel Pipe Thread)

Full name: British Standard Pipe Parallel thread (British Standard Pipe Parallel Thread)

Standard: In accordance with BS 2779/ISO 228-1.

Characteristics: Straight thread without taper, also with 55° thread angle.

Sealing mechanism: requires an additional sealing washer (usually an O-ring or flat washer) on the end face of the fitting to achieve a seal.

BSPT vs BSPP Difference Explained

| Parameter | BSPT (R Series) | BSPP (G Series) |

| Thread Type | Tapered | Parallel |

| Sealing Method | Thread Deformation Seal | Gasket/O-Ring Seal |

| Pressure Rating | Higher (up to 300 bar) | Lower (typically <100 bar) |

| Common Sizes | 1/16“ to 6” | 1/16“ to 6” |

| Teeth per inch | same as BSPP | same as BSPT |

| Marker Example | R1/2 | G1/2 |

Comparison of BSPT vs BSPP Thread Specification and Dimension Table

BSPT Thread Size Chart

| Inch size | Dash size | Thread Size | Male Thread O.D. (in) | Female thread O.D (in) | ||

| 1⁄8 | -2 | 1⁄8 – 28 | 3⁄8 | 0.38 | 11⁄32 | 0.35 |

| 1⁄4 | -4 | 1⁄4 – 19 | 33⁄64 | 0.52 | 15⁄32 | 0.47 |

| 3⁄8 | -6 | 3⁄8 – 19 | 21⁄32 | 0.65 | 19⁄32 | 0.60 |

| 1⁄2 | -8 | 1⁄2 – 14 | 13⁄16 | 0.82 | 3⁄4 | 0.75 |

| 5⁄8 | -10 | 5⁄8 – 14 | 7⁄8 | 0.88 | 13⁄16 | 0.80 |

| 3⁄4 | -12 | 3⁄4 – 14 | 1 1⁄32 | 1.04 | 31⁄32 | 0.97 |

| 1 | -16 | 1 – 11 | 1 5⁄16 | 1.30 | 1 7⁄32 | 1.22 |

| 1 1⁄4 | -20 | 1 1⁄4 – 11 | 1 21⁄32 | 1.65 | 1 9⁄16 | 1.56 |

| 1 1⁄2 | -24 | 1 1⁄2 – 11 | 1 7⁄8 | 1.88 | 1 25⁄32 | 1.79 |

| 2 | -32 | 2 – 11 | 2 11⁄32 | 2.35 | 2 1⁄4 | 2.26 |

BSPP Thread Size Chart

| Inch size | Dash size | Thread Size | Male Thread O.D. (in) | Female thread O.D (in) | ||

| 1⁄8 | -2 | 1⁄8 – 28 | 3⁄8 | 0.38 | 11⁄32 | 0.35 |

| 1⁄4 | -4 | 1⁄4 – 19 | 33⁄64 | 0.52 | 15⁄32 | 0.47 |

| 3⁄8 | -6 | 3⁄8 – 19 | 21⁄32 | 0.65 | 19⁄32 | 0.60 |

| 1⁄2 | -8 | 1⁄2 – 14 | 13⁄16 | 0.82 | 3⁄4 | 0.75 |

| 5⁄8 | -10 | 5⁄8 – 14 | 7⁄8 | 0.88 | 13⁄16 | 0.80 |

| 3⁄4 | -12 | 3⁄4 – 14 | 1 1⁄32 | 1.04 | 31⁄32 | 0.97 |

| 1 | -16 | 1 – 11 | 1 5⁄16 | 1.30 | 1 7⁄32 | 1.22 |

| 1 1⁄4 | -20 | 1 1⁄4 – 11 | 1 21⁄32 | 1.65 | 1 9⁄16 | 1.56 |

| 1 1⁄2 | -24 | 1 1⁄2 – 11 | 1 7⁄8 | 1.88 | 1 25⁄32 | 1.79 |

| 2 | -32 | 2 – 11 | 2 11⁄32 | 2.35 | 2 1⁄4 | 2.26 |

Note: Although the dimensional parameters are the same, due to the taper of the BSPT, the actual measurement of the diameter will vary with the position of the

BSPT vs BSPP difference identification method

BSPT vs BSPP Appearance

- Observe the taper:

BSPT: The thread diameter increases gradually from the end to the inside.

BSPP: Thread diameter remains the same, no change. - Thread marking:

BSPT is usually marked with “R” (e.g. R1/2″) or ‘PT’.

BSPP is usually marked with “G” (e.g. G1/2″) or ‘PS’. - Measuring method:

Use calipers to measure the thread diameter at different positions, if there is a significant change, it is BSPP.

Use thread gauge to check taper

BSPT vs BSPP function difference

- Sealing method:

BSPT: The thread itself provides sealing

BSPP: additional seals are required - Mating method:

BSPT usually fits with BSPT or BSPP (the latter requires a gasket).

BSPP usually mates with BSPP and must be gasketed.

BSPT vs BSPP Usage

Typical applications for BSPT

High pressure hydraulic systems

Gas piping systems

Where metal-to-metal sealing is required

High temperature applications (due to lack of elastic seals)

Petrochemical and energy industry piping connections

Typical applications for BSPP

Low pressure hydraulic systems

Water treatment systems

Connections requiring frequent disassembly

Food and pharmaceutical industry (easy cleaning)

Pneumatic systems

BSPT vs BSPP Compatibility Analysis

BSPT vs BSPP Intermating possibilities

BSPT male thread with BSPP female thread:

Can be mated, but gasket required

Not recommended for high pressure applications

BSPP male vs BSPT female:

Theoretically possible, but sealing is not reliable

Should be avoided in practice

BSPT vs BSPPSame type fit:

BSPT-BSPT: optimal sealing performance

BSPP-BSPP: gasket must be used

Compatibility with other thread standards

Incompatible with NPT threads (although both are tapered threads, the angle and pitch are different)

Completely incompatible with metric threads

BSPT vs BSPP Sealing Mechanism Explained

BSPT sealing principle

Taper fit: as the thread is tightened, radial pressure is generated on the taper surface.

Metal deformation: the appropriate amount of surplus leads to a slight metal deformation to achieve sealing

Secondary sealing: Usually requires thread sealant or PTFE tape to fill microscopic gaps.

BSPP Sealing Principle

Face sealing: relies on compression of the joint face and gasket

Sealing element:

O-Ring: elastic seal, suitable for a wide range of media.

Flat gasket: usually metal or composite material

Compression control: the key parameter, too small will leak, too large will damage the seal

BSPT vs BSPP Installation Methods Comparison

BSPT Installation Procedure

- Clean the thread surface

- Wrap PTFE tape around the male threads (clockwise, 2-3 layers).

- Apply appropriate amount of thread sealant (optional)

- Screw in manually until tight to the touch.

- Use tool for final tightening 1-2 turns (avoid over-tightening)

- Pressure test

BSPP Installation Procedure

- Check gasket condition (replace damaged gasket)

- Clean the connection surface

- Place the gasket correctly (O-ring needs to be in the groove)

- manually align and screw in

- Tighten bolts/nuts evenly (if any)

- Tighten flanged connections progressively in diagonal order.

BSPT vs BSPP Installation Precautions

BSPT: Avoid over-tightening which may distort the threads.

BSPP: Ensure that the gasket is properly seated.

Both: Prohibit the use of raw tape as the only means of sealing BSPP.

BSPT vs BSPP Selection Basis and Advantages and Disadvantages Analysis

Pressure Rating:

High pressure: BSPT preferred

Low pressure: BSPP is more economical

Media Characteristics:

Corrosive media: BSPT more reliable

High cleaning requirements: BSPP easier to maintain

Temperature conditions:

High temperature: BSPT (without elastic seals)

Normal temperature: both can be

Vibration environment:

High vibration: BSPT more resistant to loosening

Stable environment: both

Advantages and disadvantages of BSPT vs BSPP

BSPT Advantages:

Higher pressure tolerance

Better temperature resistance

No additional seals required

More resistant to vibration loosening

BSPT Disadvantages:

May require re-threading after disassembly

Higher installation requirements (tightness control)

Not suitable for frequent disassembly

BSPP Advantages:

Easy to install

Easy to disassemble for maintenance

Replaceable gaskets

Face seals are more reliable for low pressure applications

BSPP Disadvantages:

Seal deterioration problems

Lower pressure limits

Additional sealing elements required

BSPT vs BSPP Common Problems and Solutions

BSPT Common Problems

- Leakage problems:

Cause: Inadequate fastening, thread damage, insufficient sealant.

Solution: Reinstall and repair threads if necessary. - Seized threads:

Cause: Over-tightening, poor metal compatibility

Prevention: Use anti-seize lubricant, avoid over-torque. - Difficulty in installation:

Cause: Taper mismatch, thread damage

Inspection: Verify specifications with a thread gauge

BSPP Common Problems

- Gasket failure:

Reason: incompatible materials, excessive compression

Solution: Choose the right material for the gasket and control the compression amount. - End face damage:

Reason: over-tightening, surface roughness

Prevention: Use torque wrenches to ensure the smoothness of the end face. - Wrong installation:

Common mistake: trying to use raw material tape instead of gasket sealing

Correction: Use the specified seals in strict accordance with the requirements

BSPT vs BSPP Common Problems

- Misidentification of thread type:

Consequence: Misfit leads to leakage

Prevention: Clear marking system, train personnel to recognize - Corrosion problem:

Countermeasure: choose the right material according to the medium (e.g. 316 stainless steel) - Maintenance problems:

Suggestion: establish a regular inspection system, especially vibration environment

BSPT vs BSPP Industry Application Trends

- High-pressure field: BSPT is still dominant, but ferrule fittings are gradually replaced

- food and medicine: BSPP’s hygienic design is more popular

- pneumatic system: BSPP is dominant, with the development of quick coupling

- Energy industry: BSPT is still the standard choice for high-pressure pipelines.

See also: jic vs npt vs bsp thread differences

Conclusion:

The correct selection and use of BSPT/BSPP threads is critical to system reliability, taking into account factors such as pressure, media, temperature and maintenance requirements. In practical applications, it is recommended to establish a clear labeling system and installation specifications to ensure connection reliability and reduce the failure rate, if you have other related questions about BSPT vs BSPP you can consult our technical engineers, they will answer your questions for free.