SAE and NPT threads are two common American Standard thread standards used in hydraulic systems. There are significant differences in their structural design, sealing mechanisms and application scenarios. The following is a comparison of the characteristics of the two from multiple dimensions to help users choose and use them correctly.

Meaning and characteristics of SAE threads

Full name: SAE J514 standard (Society of Automotive Engineers), commonly used in hydraulic systems.

Structure: straight thread (parallel thread) + O-ring / metal gasket sealing.

Typical models: SAE4 (7/16“20), SAE6 (9/16”18), etc., the number represents the size code.

Sealing mechanism: relies on the compression deformation of the O-ring or gasket to achieve sealing, independent of the thread itself.

Related Article Recommendations:

Key Differences Between JIC and SAE Hydraulic Fittings and Selection Guide

NPT thread meaning, characteristics

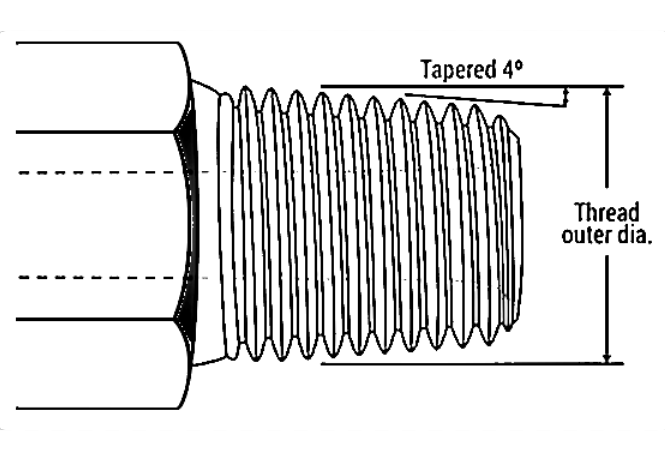

Full name: National Pipe Thread Taper, American National Standard Tapered Pipe Thread.

Structure: tapered thread (taper 1:16, i.e., 1/16 inch diameter change per inch of length).

Typical types: 1/8“27 NPT, 1/4”18 NPT, etc. Numbers indicate nominal pipe diameter and number of teeth per inch.

Sealing Mechanism: Relies on extruded deformation of the metal as the threads engage and a sealant (e.g., raw material tape) to fill the gap.

Related Article Recommendations:

Detailed guide to NPT vs NPTF thread differences

National Pipe Tapered NPT vs National Pipe Straight NPS

SAE vs NPT Threads Key Parameter Comparison

| Parameters | SAE Threads | NPT Threads |

| Thread Type | Straight (Parallel) | Tapered (1:16 Taper) |

| Sealing Method | O-Ring/Gasket | Thread Deformation + Sealant |

| Thread Angle | 60° | 60° |

| Pressure classes | High pressure (up to 700 bar) | Medium-low pressure (typically <100 bar) |

| Reusability | High (O-rings can be replaced) | Low (prone to leakage with multiple disassemblies) |

| Installation Tools | Torque Wrench (to control preload) | Raw Material Tape/Sealant + Hand Tighten |

SAE vs NPT Thread Size Chart

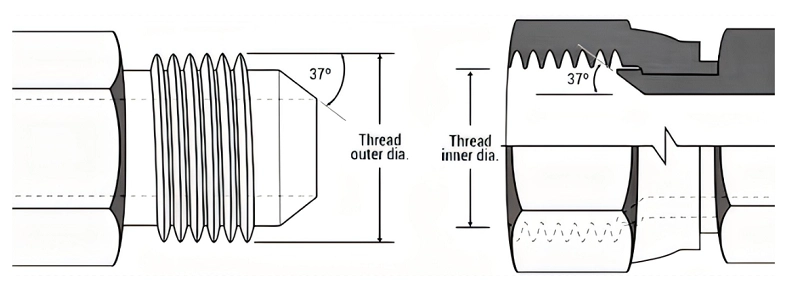

JIC 37° Flare (SAE J514)

| Inch size | Dash size | Thread Size | Male Thread O.D. (in) | Female thread O.D (in) | ||

| 1⁄8 | -2 | 5⁄16 – 24 | 5⁄16 | 0.31 | 9⁄32 | 0.27 |

| 3⁄16 | -3 | 3⁄8 – 24 | 3⁄8 | 0.38 | 11⁄32 | 0.34 |

| 1⁄4 | -4 | 7⁄16 – 20 | 7⁄16 | 0.44 | 13⁄32 | 0.39 |

| 5⁄16 | -5 | 1⁄2 – 20 | 1⁄2 | 0.50 | 15⁄32 | 0.45 |

| 3⁄8 | -6 | 9⁄16 – 18 | 9⁄16 | 0.56 | 17⁄32 | 0.51 |

| 1⁄2 | -8 | 3⁄4 – 16 | 3⁄4 | 0.75 | 11⁄16 | 0.69 |

| 5⁄8 | -10 | 7⁄8 – 14 | 7⁄8 | 0.88 | 13⁄16 | 0.81 |

| 3⁄4 | -12 | 1 1⁄16 – 12 | 11⁄16 | 1.06 | 1 | 0.98 |

| 7⁄8 | -14 | 1 3⁄16 – 12 | 1 3⁄16 | 1.19 | 1 1⁄8 | 1.10 |

| 1 | -16 | 1 5⁄16-12 | 1 5⁄16 | 1.31 | 1 1⁄4 | 1.23 |

| 1 1⁄4 | -20 | 1 5⁄8 – 12 | 1 5⁄8 | 1.63 | 1 9⁄16 | 1.54 |

| 1 1⁄2 | -24 | 1 7⁄8 – 12 | 1 7⁄8 | 1.88 | 1 13⁄16 | 1.79 |

| 2 | -32 | 2 1⁄2 – 12 | 2 1⁄2 | 2.50 | 2 7⁄16 | 2.42 |

National Pipe Tapered Fuel (NPTF)

| Inch size | Dash size | Threads per Inch | Male Thread O.D. (in) | Female thread O.D (in) | ||

| 1⁄8 | -2 | 27 | 13⁄32 | 0.41 | 3⁄8 | 0.38 |

| 1⁄4 | -4 | 18 | 17⁄32 | 0.54 | 1⁄2 | 0.49 |

| 3⁄8 | -6 | 18 | 11⁄16 | 0.68 | 5⁄8 | 0.63 |

| 1⁄2 | -8 | 14 | 27⁄32 | 0.84 | 25⁄32 | 0.77 |

| 3⁄4 | -12 | 14 | 1 1⁄16 | 1.05 | 1 | 0.98 |

| 1 | -16 | 11 1⁄2 | 1 5⁄16 | 1.32 | 1 1⁄4 | 1.24 |

| 1 1⁄4 | -20 | 11 1⁄2 | 1 21⁄32 | 1.66 | 1 19⁄32 | 1.58 |

| 1 1⁄2 | -24 | 11 1⁄2 | 1 29⁄32 | 1.90 | 1 13⁄16 | 1.82 |

| 2 | -32 | 11 1⁄2 | 2 3⁄8 | 2.38 | 2 5⁄16 | 2.30 |

How to distinguish between SAE and NPT threads?

- Visual inspection

Taper: NPT threads gradually increase in diameter at the root, SAE threads remain parallel.

Thread end: NPT usually has a tapered end, SAE is flat. - Measuring tools

Use a thread gauge to measure taper, or compare thread lengths: NPT has a longer effective engagement length for the same nominal size.

Are SAE and NPT threads compatible?

Not compatible

Core reasons for incompatibility

- Different thread types

SAE thread: Straight thread (parallel thread), thread diameter is the same from end to end.

NPT thread: Tapered thread (1:16 taper), the diameter of the root of the thread increases gradually.

Consequence: NPT threads require a taper fit to seal, while SAE straight threads do not fit the taper perfectly, resulting in a poor engagement. - Different pitches (teeth per inch)

For example: the same as the 1/4 inch specifications:

SAE: Common pitch is 19 teeth per inch (SAE4).

NPT: standard pitch is 18 teeth / inch (NPT 1/4 “18).

Consequences: the pitch difference leads to threads can not be correctly bite, forcibly screwed into the threads will be scratched, damage to the sealing surface. - Conflicting sealing mechanisms

SAE: rely on O-ring or gasket compression sealing, the thread itself does not assume the sealing function.

NPT: rely on the metal extrusion deformation of the conical thread and sealant (such as raw material tape) to fill the gap.

Consequence: If an SAE fitting is forced into an NPT port, the O-ring will not compress effectively and the tapered thread will not form an effective seal.

Risks of forcibly mixing SAE and NPT threads

Thread damage

The tapered threads of NPT are fragile, and the root of the threads is susceptible to cutting or deformation when forced with straight SAE threads.

Repeated disassembly and reassembly may result in complete thread failure beyond repair.

Seal failure

SAE O-rings do not compress evenly due to incomplete thread engagement, resulting in leakage.

NPT-dependent taper seals have difficulty filling gaps even with raw material tapes because straight threads do not fit.

System Pressure Leaks or Bursts

In high-pressure scenarios (e.g., hydraulic systems), mixing may lead to sudden failure at the joint, triggering a safety hazard.

Alternative to SAE and NPT threads: use an adapter

If SAE and NPT connections must be connected, transition through an adapter is required:

Adapter type

Example: SAE straight thread to NPT tapered thread adapter (e.g. SAE JIC 37° to NPT fitting).

The internal ends of the adapter match the SAE and NPT thread parameters to ensure sealing compatibility.

Caution

Selection of adapters should be matched to pressure ratings (e.g. SAE high pressure adapters need to withstand the maximum system pressure).

The sealing material must be compatible with the media (e.g. oil resistant O-rings for fuel systems).

Related Article Recommendations:

The Ultimate Selection Guide for JIC and NPT Fittings

SAE and NPT thread practical application recommendations

- Prohibit direct mixing: SAE and NPT threads can not be directly connected, must be transitioned through the adapter. 2.

- clear marking: in the equipment and pipe labeling thread type (such as engraved “SAE” or “NPT”), to avoid misinstallation. 3. testing and verification: after installation, the need for O-rings.

- Test verification: pressure test (e.g. 1.5 times working pressure holding pressure test) should be carried out after installation to ensure reliable sealing.

SAE and NPT Thread Application Scenarios and Advantages and Disadvantages

| Types | Advantages | Disadvantages | Typical Uses |

| SAE | Reliable high-pressure sealing, easy disassembly and installation | High cost, need to replace the O-ring periodically | Construction machinery, hydraulic cylinders, fuel system |

| NPT | Low cost, versatile | Dependent on installation skills, prone to leakage | Water, gas, low-pressure chemical pipes |

SAE and NPT Thread Sealing Mechanisms Explained

SAE sealing:

O-ring (material such as nitrile rubber, fluorine rubber) in compression to fill the gap, the higher the pressure the stronger the sealing effect.

NPT sealing:

Radial pressure is generated when the tapered threads are engaged, with raw material tape (PTFE) or sealant to fill the microscopic gap.

SAE and NPT thread installation method

SAE Thread Installation

Clean threads and apply grease.

Install the O-ring (avoid twisting) and tighten with a torque wrench according to the standard .

NPT Thread Installation

Wrap 35 layers of raw material tape clockwise along the threads (or apply sealant).

After hand tightening, use a wrench to turn the thread an additional 1.52 turns to ensure a full taper fit.

Recommendations for SAE and NPT Thread Selection

Scenarios for SAE: high pressure, frequent disassembly, highly corrosive media (e.g. hydraulic oil, fuel).

Choose NPT scenarios: low pressure, static piping, cost-sensitive (such as tap water, compressed air).

SAE and NPT thread common problems and solutions

- NPT thread leakage

Cause: Insufficient raw material tape or thread damage.

Solution: Re-wrap the raw material tape after disassembly or use liquid sealant. - SAE fitting O-ring deterioration

Cause: Hardened rubber due to high temperature or chemical corrosion.

Solution: Replace with media resistant O-rings (e.g. Viton). - Misuse of threads leading to seizure

Prevention: Test screwing with a sample before installation to make sure the thread type matches.

Summarize

The design logic of SAE and NPT threads is very different: SAE achieves reliability through additional seals, while NPT relies on structural self-sealing to reduce costs. The right choice requires consideration of pressure, media, maintenance frequency and cost. SAE is preferred for high-pressure dynamic systems, while NPT is better suited for low-pressure static piping to avoid system failure due to misuse. This article would like to write about the difference between SAE and NPT threads, compatibility and other issues, if you have other questions about SAE and NPT threads, please contact our technical engineers, he will be free to answer your questions.