Hose Ferrule is a small but vital part of hydraulic systems and industrial fluid transfer. As the key component connecting the hose to the coupling, it directly affects the sealing, safety and service life of the entire system. According to industry statistics, more than 35% of hydraulic system failures result from improper collar selection or installation. This article will take you a comprehensive understanding of the hose collar, to help you make informed purchasing decisions.

1.1 Definition and Function of Hose Ferrule

A hose ferrule (Ferrule) is a metal ring-shaped part that is mainly used to:

Secure the connection between hydraulic hoses and fittings

Provide a reliable sealing performance

Enhance the tensile strength of the connection

Prevent the hose from disconnecting under high pressure

“The ferrule may be small, but it’s the ‘safety guard’ of the hydraulic system.” –Parker Hannifin Technical Brochure

1.2 Common types of Hose Ferrule

Classification by structure:

| Type | Features | Scenarios |

| Single layer collar | Simple construction, low cost | Low pressure systems (<3000PSI) |

| Double layer collar | Reinforced design for greater durability | High pressure systems (>3000PSI) |

| Reusable collar | Threaded and removable | Devices that require frequent maintenance |

Hose Ferrule Classification by material:

Carbon steel ferrule: economical, need surface treatment to prevent rust

Stainless steel ferrule: corrosion-resistant, suitable for harsh environments

Brass ferrule: Good electrical conductivity, used in special occasions

2.1 Key Parameters for Size Selection

There are three core dimensions that must be considered when selecting a ferrule:

1. Hose Inside Diameter (ID): Determine the flow rate

2. Hose OD (Outside Diameter): Determine the inner diameter of the ferrule

3. Fitting type: Match with different standards such as JIC, NPT, etc.

Practical tip: When using digital calipers to measure, take 3 measurements at different positions of the hose and take the average value to ensure the accuracy.

2.2 Hose Ferrule Industry Standards Comparison Table

Standard System SAE, Typical Code J516, Commonly Used Area: America.

Standard system DIN, typical code 2353, common area: Europe.

Standard system GB/T, typical code 3765, commonly used area: China.

Standard system JIS, Typical code B8363, Commonly used area: Japan.

3.1 Necessary tools list

1. Hydraulic crimping machine: recommended Parker Hannifin PF series

2. Specialized cutter: to ensure a flat cut

3. Deburring tool: to deal with the cutting edge

4. Measuring tools: digital calipers (accuracy of 0.01mm)

3.2 Six-step standard installation process

1. Measuring mark: to mark the insertion depth on the hose

2. Cutting treatment: Use special tools to cut vertically

3. Cleaning preparation: Clean the contact surface with a lint-free cloth

4. Sleeve positioning: Ensure that the sleeve is aligned with the marking

5. Crimping operation:

Choose the right mold

Pressurize in stages (pre-pressure and then final pressure)

6. Quality check:

Visual inspection of no deformation

Measurement of the diameter of the crimped

Safety Warning: When crimping, the operator should wear protective eyewear, to avoid injuries caused by metal shavings.

3.3 Common Mistakes and How to Avoid Them

| Incorrect Operation | Consequences | Correct Practice |

| Crimp with ordinary pliers | Poor sealing | Use a special crimper |

| Neglect cleaning procedure | Particle contamination | Strict cleaning procedure |

| Over crimp | Hose damage | Operate to standard pressure |

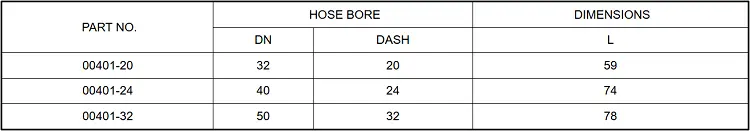

hydraulic ferrule 00401 Size Chart.webp

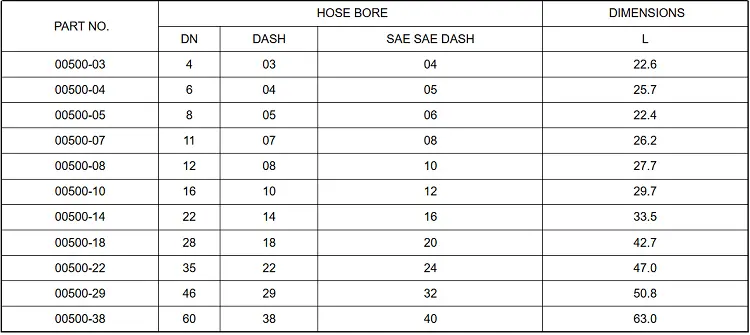

hydraulic ferrule 00500 Size Chart

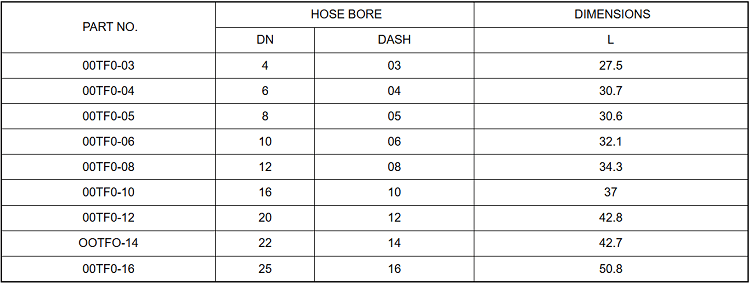

hydraulic ferrule 00tf0 Size Chart

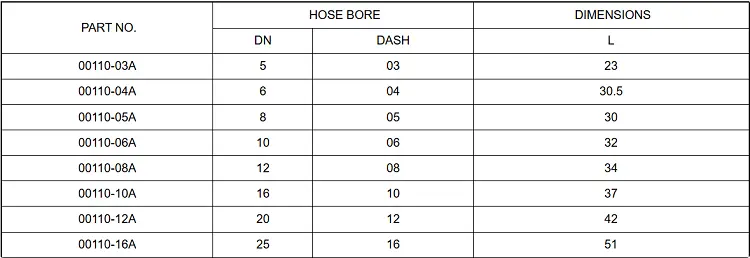

hydraulic ferrule 00100 Size Chart

| Descriptive | Material | prices | Delivery time |

| 00210-04 Carbon Steel No Skiving Hose Sleeve R1 R2 R3 R4 4SP 4SH 6SH 03310 00210 00400 Hydraulic Hose Crimping Fittings Ferrule | Carbon Steel | From 0.15 USD/piece | 15-25 Days |

| 00402-16 High Pressure Hose Ferrule Fittings Carbon Steel Zinc Plated Interlock Hydraulic Hose Ferrule | Carbon Steel | 0.90-1.50 USD/piece | 15-25 Days |

| 00TF0 Hose Sleeves Hydraulic Ferrules Medium Pressure Sockets for PTFE Hose SAE 100 R4 | Carbon Steel | 0.50-10.99 USD/piece | 15-25 Days |

| 03310 Hydraulic Hose Crimping Ferrule Hose Ferrule Stainless Steel Hydraulic Hose Ferrule | Carbon Steel | 0.35-3.5 USD/piece | 15-25 Days |

| 3/8″ 00TF0-06 Crimpes Hydraulic Fitting Connector Stainless Steel Ferrule for PTFE Hose | Carbon Steel | 0.50-10.99USD/piece | 15-25 Days |

| Ferrule-Ferrule for 4SH/R12/32 Hose-Parker Series ASK PG5/00401 | Stainless Steel | 0.25-11.99 USD/piece | 15-25 Days |

4.1 Hose Ferrule Leakage Troubleshooting Chart

Hose Ferrule Oil Seepage from Fittings

Possible Causes:

1. Mismatch of ferrule sizes (40%)

2. Inadequate crimp (30%)

3. Hose deterioration (20%)

4. Miscellaneous (10%)

Solutions:

1. Remeasure and replace with appropriate ferrule 2. Replace with a suitable collar

2. Check crimping force with a torque wrench

3. Replace the complete hose assembly

4.2 Hose Ferrule Rust Treatment Plan

Preventive measures:

Use stainless steel collars in wet environments

Apply rust inhibiting grease regularly

Carry out a complete inspection once a year

Emergency treatment:

1. Minor corrosion: Clean with a wire brush and apply rust inhibiting paint

2. Severe corrosion: Replace the complete connection immediately

With the systematic introduction in this article, you have acquired a complete body of knowledge from the basics to purchasing decisions. In practical application, it is recommended to set up a standardized file for the use of the collar to record each replacement and maintenance, which will greatly improve the reliability and safety of the system.

How to recognize the size of Hose Ferrule?

The ferrule size usually corresponds to the hose size, and the following parameters need to be measured:

Hose Inside Diameter (ID): e.g. 3/8″, 1/2.

Hose Outside Diameter (OD): affects the choice of ferrule ID (e.g. 1/2″ hose OD is about 0.75″).

Sleeve Type: Single (light duty) or double (heavy duty, high pressure resistant).

Cross Reference Example:

| Hose Size (ID) | Sleeve ID (mm) | Applicable Pressure Rating |

| 1/4″ | 6-7mm | ≤3000 PSI |

| 3/8 “ | 9-10mm | ≤4000 PSI |

| 1/2″ | 12-13mm | ≤6000 PSI |

Can the ferrule be reused?

Permanent collar: not reusable after crimping (destructive installation).

Reusable collars: e.g. Parker 71/73 series, with threads that can be removed, but the sealing needs to be checked regularly.

(Special customization available, free samples)

China Huiqi (Beijing) Technology Co., Ltd, with fifteen years of excellence, is a professional manufacturer of high quality hydraulic hose fittings, hydraulic hose couplings, hydraulic hose fittings, hydraulic adapters and hydraulic fittings. We offer a wide range of products, including thousands of unique types and sizes of hydraulic fittings, and our comprehensive solutions meet the needs of different industries, ensuring reliable performance and adaptability to a wide range of job requirements.

Our modern manufacturing facility is equipped with 16 automatic CNC lathes and supported by 75 experienced technicians to ensure high precision and consistency in every hydraulic fitting.

Our factory-professional sales team of more than 10 professionals is dedicated to providing exceptional customer service and support. From consultation to post-sale assistance, our team ensures seamless communication, customized solutions and timely responses to meet your unique needs.

What are the main types of our hydraulic fittings:

1, Rings, matching with many kinds of pipes, such as SAE, DIN, EN, GB, etc.

Flat seal fittings, multi-seal fittings, spherical seal fittings, 60°taper seal fittings, 74°taper seal fittings, 24°taper O-ring L.T. fittings, 24°taper O-ring H.T. fittings, JIS 60°taper seal fittings, riser fittings, Japanese metric fittings, etc.;3, British style pipe fittings

3,British style pipe fittings

JIS BSP 60°taper sealing fittings, BSPT fittings, BSP multi-seal fittings, BSP flat sealing fittings, BSP O-ring sealing fittings

4,U.S. Pipe Fitting

NPT nipple, JIC 74°taper sealing nipple, NPSM 60°taper sealing nipple, ORFS flat sealing nipple, SAE O-ring sealing nipple

5, One Piece Fittings

JIC, BSP, Metric, Flange

6, Flange

SAE Code 62 Flanges, SAE Code 61 Flanges, CAT Flanges

Click below to get a free consultation with a technical engineer on WhatsApp!

Add engineer number 86 13311237753 directly on Whatsapp to connect online.