NPT, NPTF, NPS, NPSM Threads: Basic Meaning and Usage

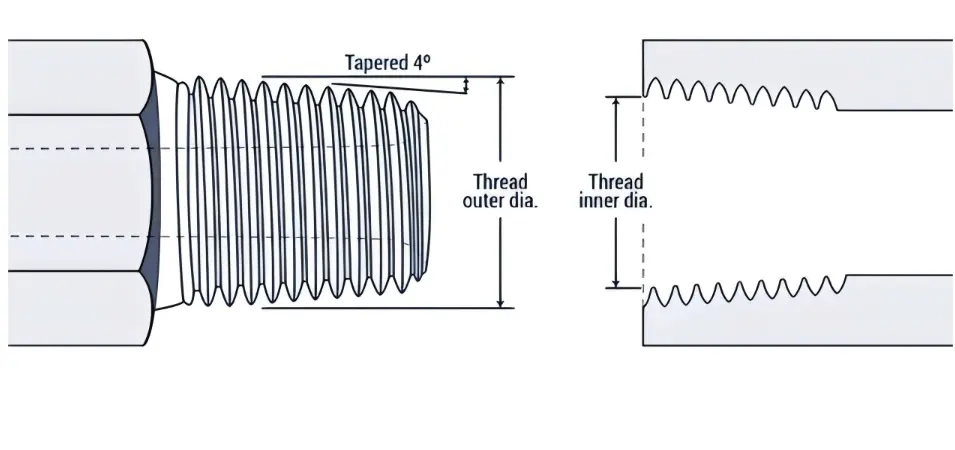

NPT (National Pipe Taper) meaning:

NPT is the most commonly used standard for tapered pipe threads in the U.S. The threads have a 1:16 taper (1/16 inch diameter change per inch of length).

Uses:

Commonly used in piping systems in North America

Suitable for water, gas, oil and other fluid transportation systems

Commonly used in low and medium pressure applications

NPTF (National Pipe Taper Fuel) meaning:

NPTF is a modified version of NPT and is designed to provide a seal without the need for sealants.

applications without the need for a sealant:

Fuel systems

Hydraulic systems

Where a leak-free seal is required

Chemical and petrochemical industries

NPS (National Pipe Straight) meaning:

NPS is a parallel (non-tapered) pipe thread with no taper compared to NPT.

Usage:

Mechanical connections rather than sealing connections

Used with flanges or gaskets

Where frequent disassembly is required

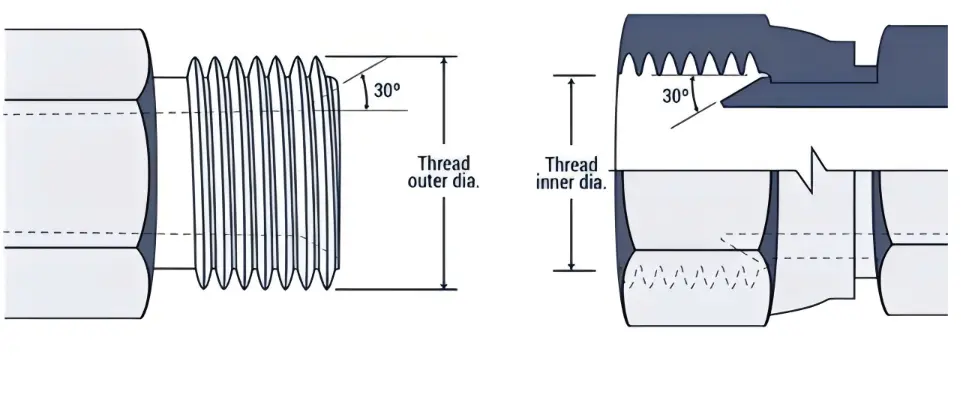

NPSM (National Pipe Straight Mechanical) meaning:

NPSM is a straight pipe thread for mechanical joints.

Purpose: NPSM is a straight pipe thread used for mechanical joints:

Mainly used for mechanical joints but not for sealing

Used in conjunction with gaskets or O-rings

Fittings that require free rotation

Key difference:

NPT is used for most common piping systems (e.g., water pipes, gas pipes).

NPTF is used for high sealing requirements (e.g. fuel systems, hydraulic systems).

NPS is only used for mechanical fixing (e.g. pipe hoops, support structures).

NPSM is used for connections requiring rotation or frequent disassembly (e.g. hose couplings).

NPTF thread sizes chart

| Inch size | Dash size | Threads per Inch | Male Thread O.D. (in) | Female thread O.D (in) | ||

| 1⁄8 | -2 | 27 | 13⁄32 | 0.41 | 3⁄8 | 0.38 |

| 1⁄4 | -4 | 18 | 17⁄32 | 0.54 | 1⁄2 | 0.49 |

| 3⁄8 | -6 | 18 | 11⁄16 | 0.68 | 5⁄8 | 0.63 |

| 1⁄2 | -8 | 14 | 27⁄32 | 0.84 | 25⁄32 | 0.77 |

| 3⁄4 | -12 | 14 | 1 1⁄16 | 1.05 | 1 | 0.98 |

| 1 | -16 | 11 1⁄2 | 1 5⁄16 | 1.32 | 1 1⁄4 | 1.24 |

| 1 1⁄4 | -20 | 11 1⁄2 | 1 21⁄32 | 1.66 | 1 19⁄32 | 1.58 |

| 1 1⁄2 | -24 | 11 1⁄2 | 1 29⁄32 | 1.90 | 1 13⁄16 | 1.82 |

| 2 | -32 | 11 1⁄2 | 2 3⁄8 | 2.38 | 2 5⁄16 | 2.30 |

NPSM thread sizes chart

| Inch size | Dash size | Threads per Inch | Male Thread O.D. (in) | Female thread O.D (in) | ||

| 1⁄8 | -2 | 27 | 13⁄32 | 0.41 | 3⁄8 | 0.38 |

| 1⁄4 | -4 | 18 | 17⁄32 | 0.54 | 1⁄2 | 0.49 |

| 3⁄8 | -6 | 14 | 11⁄16 | 0.68 | 5⁄8 | 0.63 |

| 1⁄2 | -8 | 14 | 27⁄32 | 0.84 | 25⁄32 | 0.77 |

| 3⁄4 | -12 | 14 | 1 1⁄16 | 1.05 | 1 | 0.98 |

| 1 | -16 | 11 1⁄2 | 1 5⁄16 | 1.32 | 1 1⁄4 | 1.24 |

| 1 1⁄4 | -20 | 11 1⁄2 | 1 21⁄32 | 1.66 | 1 19⁄32 | 1.58 |

| 1 1⁄2 | -24 | 11 1⁄2 | 1 29⁄32 | 1.90 | 1 13⁄16 | 1.82 |

| 2 | -32 | 11 1⁄2 | 2 3⁄8 | 2.38 | 2 5⁄16 | 2.30 |

NPT vs NPTF vs NPS vs NPSM Technical Parameters Comparison

| Parameters | NPT | NPTF | NPS | NPSM |

| Thread Shape | Tapered | Tapered | Straight | Straight |

| Seal Type | Sealant Required | Dry Seal | No Seal | Gasket Required |

| Taper | 1:16 | 1:16 | none | none |

| Pressure Rating | Medium Low Pressure | Medium High Pressure | Low Pressure | Medium Pressure |

| Application Temperatures | 20~200°C | 50~250°C | 20~100°C | 40~150°C |

| Major Standards | ASME B1.20.1 | ASME B1.20.3 | ASME B1.20.1 | ASME B1.20.1 |

NPT vs NPTF vs NPS vs NPSM Sealing Method Details

| Type | Sealing Method | Whether sealant is required |

| NPT | dependent on thread taper + sealant (e.g., biotape, sealant) | required (otherwise may leak) |

| NPTF | Dryseal, relies on precision-machined thread deformation for sealing | Not required (but sealant can still be added for extreme conditions) |

| NPS | Not for sealing, for mechanical connection only | Not applicable (with flange or weld seal) |

| NPSM | mating gasket or O-ring seal required | not required (but additional seals needed |

NPT vs NPTF vs NPS vs NPSM Sealing Key Differences:

NPT requires a sealant (e.g., raw tape, thread adhesive) or it may leak.

NPTF is designed to be a dry seal and theoretically does not require a sealant (but may still be used in practice).

NPS is not sealed and is only used for mechanical connections (e.g., pipe collars, fittings).

NPSM requires gaskets or O-rings (e.g., hose fittings).

NPT vs NPTF vs NPS vs NPSM Frequently Asked Questions and Selection Advice

How to choose between NPT and NPTF?

Choose NPT: General piping (water, gas, low-pressure oil) where sealants are acceptable.

Select NPTF: Fuel, hydraulic, chemical (where no leaks are required, or where sealants are not allowed).

What is the choice between NPS and NPSM?

Option NPS: Mechanical connection only, no sealing involved (e.g. structural support).

Select NPSM: Connections requiring rotation or frequent disassembly (e.g., hose fittings).

Are NPT and NPS interchangeable?

No, they are not! NPT is tapered and NPS is straight, and forcing them together could result in leakage or damage to the threads.

Can NPTF replace NPT?

Yes (NPTF is compatible with NPT), but at a higher cost. For general use, NPT is fine.

NPT vs NPTF vs NPS vs NPSM Purchasing Selection Guide

Purchasing Recommendations

- High sealing requirement? → Select NPTF (fuel oil, hydraulic system). 2.

- Ordinary piping? → Select NPT (water, gas, low pressure oil). 3.

- Mechanical connection only? → Select NPS (structural support). 4.

- Need to rotate or disassemble? → Select NPSM (hose coupling).

Selection according to media characteristics

Prefer NPTF (to reduce the risk of leakage).

Consider material compatibility (e.g. stainless steel).

High temperature media:

Consider NPTF (better sealing performance)

Note temperature limitations of sealing materials

Select based on pressure rating

Low pressure systems (<1000psi): NPT is usually sufficient Medium and high pressure systems (>1000psi): NPTF preferred

Ultra-high pressure systems: special fittings may be required instead of standard pipe threads

Key points to note when purchasing

- Thread type validation: NPT, NPTF, NPS or NPSM is required.

- Size verification:

Nominal Diameter (e.g. 1/8“, 1/4”, etc.)

Pitch (teeth per inch) - material selection:

Carbon steel: economic, good strength

Stainless steel: corrosion resistance, high cost

Brass: special applications - Cost Considerations

NPT: lowest cost, most widely used

NPTF: cost 1020% higher than NPT, but better sealing performance

NPS/NPSM: Costs comparable to NPT, but need to consider the additional cost of matching seals.

NPT vs NPTF Installation and Maintenance Recommendations

NPT Installation Points:

Use proper sealing tape or sealant

Wrap in the correct direction (clockwise)

Do not over-tighten (usually 12 turns with a tool after hand tightening).

NPTF Installation Points:

Ensure threads are clean and undamaged

Do not use sealants (otherwise dry sealing performance will be affected)

Install to recommended torque

Maintenance Recommendations:

Regularly check critical connections

Fully loosen before re-tightening to recommended torque

Check thread condition after disassembly and replace if necessary

By understanding the characteristics and differences of these thread types, engineers and purchasers can make more informed choices to ensure the reliability and safety of piping systems. If you have more questions about NPT vs NPTF vs NPS vs NPSM, please feel free to contact our engineers for free answers.