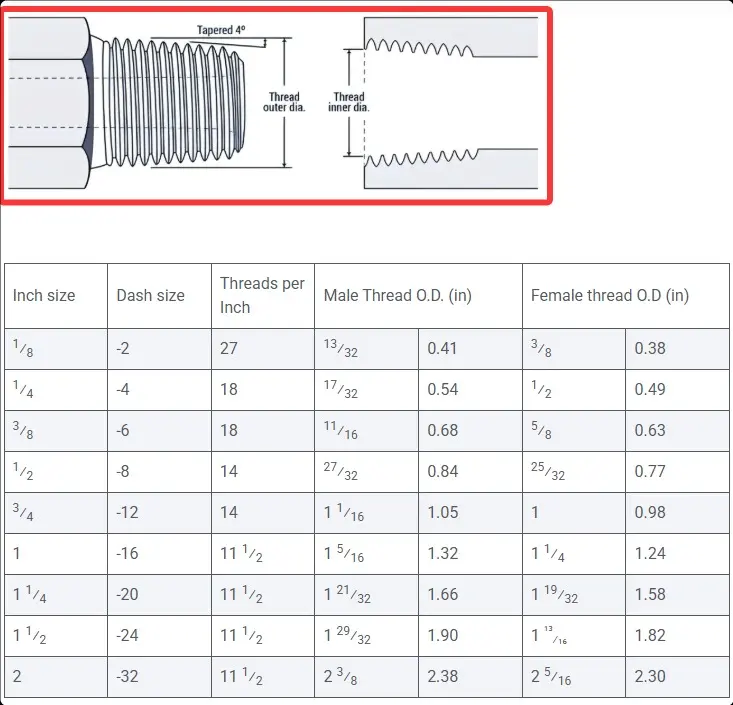

NPT Meaning:

(National Pipe Taper) American National Standard Tapered Pipe Thread, widely used in general piping connections.

Standard: Follow ASME B1.20.1 specification, thread taper is 1:16 (1/16 inch diameter change per inch length).

Thread angle: 60°.

NPTF Meaning :

(National Pipe Taper Fuel) U.S. dry-sealed tapered pipe threads, designed for high-pressure, high-risk environments where no sealant is required.

Standard: Follows SAE J476 specification, same taper as NPT (1:16), but with optimized thread profile.

Alias: Dryseal thread.

NPTF Size Chart

NPT vs NPTF Feature Comparison

| Features | NPT | NPTF |

| Thread Shape | Standard tapered threads with rounded tops and bottoms | Precision tapered threads with flatter (nearly flat) tops and bottoms |

| Seal dependent | Requires sealant (e.g., raw tape, sealant) | Relies on metal-to-metal interference fit for dry sealing |

| Tolerance Requirements | less stringent | more stringent (threaded fits need to be more accurate) |

| Application Scenarios | General-purpose low-pressure systems (water, gas, non-hazardous media) | High-pressure, high-risk systems (fuel oil, hydraulics, chemicals) |

NPT vs NPTF Core Differences

NPT vs NPTF Sealing Mechanism

NPT: Gaps are filled by thread deformation and sealing material, sealant is the key to preventing leakage.

NPTF: Precise thread design, multiple sealing lines through intermetallic interference fit, no additional sealant required.NPT vs NPTF Thread Design Differences

NPTF threads have flatter tops and bottoms, ensuring a larger metal contact area when the threads are engaged, reducing leakage paths.

NPT vs NPTF Cost and Maintenance

NPT: Low cost, but requires periodic checking of sealant condition.

NPTF: High initial cost, but low long-term maintenance (no sealant deterioration).

Are NPT vs NPTF compatible?

Mechanical compatibility: NPT and NPTF threads are the same size and taper and can be physically connected.

Sealing Compatibility:

Mixed use of NPT + NPTF: may lead to leakage (destruction of sealing threads due to differences in thread shape).

NPTF in place of NPT: feasible (requires sealant) but sacrifices dry sealing advantage.

NPT instead of NPTF: not recommended (prone to leakage in high pressure scenarios).

NPT vs NPTF sealing mechanism in detail

NPT sealing principle

When threads are tightened, the taper causes radial extrusion between the male and female threads, along with the sealant to fill the tiny gap.

Disadvantage: Sealant may be invalidated by high pressure media washout, or affected by temperature changes.

Dry sealing principle of NPTF

When the threads are engaged, the top of the external threads extrudes the bottom of the internal threads, forming several continuous metal sealing lines.

Advantages: no risk of sealant contamination, resistance to high pressure, vibration and thermal cycling.

NPT vs NPTF Installation Methods Comparison

| Steps | NPT Installation Points | NPTF Installation Points |

| Pre-treatment | Clean threads, apply sealant | Thoroughly clean threads to ensure they are free of oil, dirt and contaminants |

| Tightening Torque | Controlled torque required (over-tightening can damage threads) | Tighten to a standard torque to ensure full metal contact |

| Inspection Criteria | Check Sealant Uniformity | Check Thread Engagement to Form a Complete Seal Line |

| Common Errors | Missing sealant, under/over tightening | Thread contamination, failure to align resulting in broken sealing line |

How to choose NPT vs NPTF? Advantages and Disadvantages Analysis

| Scene | Selecting NPT | Selecting NPTF |

| Advantages | Low cost, versatile, easy to install | No risk of leakage, high pressure resistant, maintenance free |

| Disadvantages | Dependent on sealant, requires regular maintenance | High cost, requires high installation precision |

| Recommended Applications | Low Pressure Water and Gas Lines, Non-Corrosive Media, Temporary Systems | Fuel Systems, Hydraulic Systems, High Temperature/High Pressure Industrial Equipment |

| Key Decision Factors | Budget, Media Safety, Ease of Maintenance | Media Hazards, Regulatory Requirements, Long-Term Reliability |

Common Problems in the Use of NPT vs NPTF

NPT Leakage Problems

Cause: Sealant is not applied evenly, threads are worn, over-tightening causes deformation.

Solution: Reapply sealant and standardize installation, or replace with NPTF.NPTF installation failure

Cause: Thread contamination, failure to align, insufficient torque.

Solution: Reinstall after thorough cleaning and use a torque wrench to standardize the installation.Leakage due to mixing of NPT vs NPTF

Case: NPT male threads were mixed with NPTF female threads, resulting in sealing line breakage due to mismatch of tooth types.

Suggestion: Avoid mixing, add sealant if necessary and test rigorously.NPT vs NPTF standard confusion

Myth: NPTF is considered to be an “enhanced version of NPT” and can be replaced at will.

Correction: NPTF is designed for dry sealing and cannot be used as a direct replacement for NPT scenarios that require a sealant.NPT vs NPTF Summary

NPT: Economical, general purpose option for low pressure and non-critical systems that rely on sealants.

NPTF: High-end sealing solution designed for high-pressure, high-risk environments, emphasizing reliability and safety.

Core recommendation: how to choose NPT vs NPTF, choose according to the media characteristics, pressure level and regulatory requirements, give priority to follow industry standards (such as SAE J476, ASME B1.20.1), to avoid mixing to lead to systematic risk, if you still have more related questions about NPT vs NPTF, please contact our technical engineers, we will answer your questions for free.