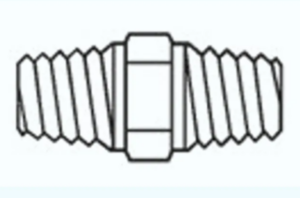

NPT hydraulic fittings are American standard tapered pipe thread fittings, this post details NPT hydraulic fittings and learn about common types, sizes, prices and and how to install them to choose the best NPT hydraulic fittings for you.

NPT hydraulic fittings (National Pipe Taper Thread) is the American standard tapered pipe thread fittings, with high sealing, strong vibration resistance and wide compatibility, it has become the core connecting parts in the fields of petroleum, chemical industry, engineering machinery and so on.

NPT

NPT (National Pipe Taper) is a 60° tapered pipe thread standard, conforming to ANSI/ASME B1.20.1 specification, and sealing is achieved by thread taper (1:16).

Characteristics of NPT threads include: conical pipe threads with an angle of 1.7899° or 1.47’24” between the taper and the center axis of the pipe, flat root and crown sections, 60° thread angle, and pitches measured in threads per inch (tpi).

Pipe threads can be designed in a variety of types suitable for use with or without thread sealant, for example, National Standard tapered pipe threads allow them to form a seal as they are tightened, with the larger diameter continually being compressed into the smaller diameter, ultimately forming a seal.

Core features include:

1. Self-sealing design: radial pressure is generated when the tapered threads are tightened, which in conjunction with a sealant (e.g., biotape) achieves a double seal;

2. High pressure resistance: suitable for hydraulic systems ≤10,000 psi (69MPa);

3. Wide range of compatibility: adaptable to AFSL hydraulic components (e.g., pumps, valves, filters), and partially compatible with NPTF (Dry Seal Threads).

1. Classified by thread type

NPT (standard tapered pipe thread): need to be used with sealing materials (such as PTFE tape), the most versatile;

NPTF (dry-seal tapered pipe thread): the top of the thread is designed as a rounded arc, no sealant can be achieved without leakage, but the cost is higher.

2. Classified by structure

Straight Fittings (NPT Straight): both ends are NPT threads, used to extend the pipeline;

Reducer Fittings (NPT Reducer): connecting different pipe diameters of the pipeline (such as 1/2 “to 3/8”);

Tee/Elbow Fittings: to change the direction of the fluid or divert the flow of the material can be selected from carbon steel, stainless steel or brass.

3. Classified by material

Stainless steel NPT fittings (304/316L): strong corrosion resistance, suitable for chemical industry, ships;

Carbon steel zinc-plated NPT fittings: economic choice, used for general industrial equipment;

Brass NPT fittings: low conductivity, suitable for flammable and explosive environments.

| Inch size | Threads per Inch | Male Thread O.D. (in) | Female thread O.D (in) | ||

| 1⁄8 | 27 | 13⁄32 | 0.41 | 3⁄8 | 0.38 |

| 1⁄4 | 18 | 17⁄32 | 0.54 | 1⁄2 | 0.49 |

| 3⁄8 | 18 | 11⁄16 | 0.68 | 5⁄8 | 0.63 |

| 1⁄2 | 14 | 27⁄32 | 0.84 | 25⁄32 | 0.77 |

| 3⁄4 | 14 | 1 1⁄16 | 1.05 | 1 | 0.98 |

| 1 | 11 1⁄2 | 1 5⁄16 | 1.32 | 1 1⁄4 | 1.24 |

| 1 1⁄4 | 11 1⁄2 | 1 21⁄32 | 1.66 | 1 19⁄32 | 1.58 |

| 1 1⁄2 | 11 1⁄2 | 1 29⁄32 | 1.9 | 1 13⁄16 | 1.82 |

| 2 | 11 1⁄2 | 2 3⁄8 | 2.38 | 2 5⁄16 | 2.3 |

Common sizes of npt threads include 1/8, 1/4, 3/8, 1/2, 3/4, 1, 1 1/4, 1 1/2, 2, 2 1/2, 3, 4, 5, and 6 inches, and can be found on most U.S. plumbing and fittings. Thread sizes smaller than 1/8 inch and larger than 6 inches are occasionally used for specific purposes. When identifying or sizing threads, the number of threads per inch and the thread O.D. are necessary because there are multiple sizes that have the same tpi. therefore, the O.D. of the pipe or fitting must be measured and compared to the thread sizing charts for identification purposes.

| Descriptive | Material | prices | Delivery time |

| Female Flange Hydraulic Hose Fitting Cast Steel Brass Stainless Steel NPT Thread-Head Model | Stainless Steel | 0.45-11.99 USD/piece | 15-25 Days |

| Stainless Hydraulic NPT Male Connector Various Tube ODs 1/8” 1/4” 3/8” 1/2” 4mm 6mm 8mm 10mm 12mm 1/2 NPT Male Pipe Fitting | Stainless Steel | 0.20-10.00 USD/piece | 15-25 Days |

| 6505-04-06 | 1/4″ NPTF Male X 3/8″ JIC Female Swivel | 2NJ-04-06 Hydraulic Adapter Carbon Steel Fitting | Stainless Steel | 0.19-15.99 USD/piece | 15-25 Days |

| Hydraulic Fittings 6mm 8mm 10mm 12mm to 3/8” NPT Stainless Steel Pipe Fitting NPT Male Connectors | Carbon Steel | 0.10-15 USD/piece | 15-25 Days |

| Carbon Steel NPT Threaded to NPS Female Adapter Hydraulic Hose Pipe Nipple Fittings | Carbon Steel | 0.20-10.99USD/piece | 15-25 Days |

| 6505-08-08 | 1/2″ NPTF Male X 1/2″ JIC Female Swivel | 2NJ-08 Hydraulic Adapter Carbon Steel Fitting | Stainless Steel | 0.15-11.99 USD/piece | 15-25 Days |

1. Thread Characteristics

Thread Angle: 60° (as opposed to 55° for BSPP/BSPT threads);

Taper Measurement: 1/16″ reduction in diameter per inch of length (1:16 taper);

Threads Per Inch (TPI): e.g. 1/8″ NPT Threads per inch (TPI): e.g. 27 TPI for 1/8″ NPT, 18 TPI for 1/4″ NPT.

2. Marking and Certification

Surface marking: Regular products are marked with the thread size (e.g. 1/2″ NPT), material code (e.g. SS316), and pressure rating.

Certified standards: Products that meet ASME B1.20.1 or MILSPEC standards are more reliable.

3. Tool Inspection

Thread Gauge Inspection: Use NPT thread plug/ring gauges to verify thread fit;

Caliper Measurement: Measure thread diameter (e.g., 13.16mm for 1/4″ NPT) and taper.

1. Preparation before installation

Cleaning of threads: Use a wire brush to remove oil or burrs from the thread surface;

Selection of sealing material: PTFE raw tape (wound 23 layers) or liquid sealant (e.g. LOCTITE 545).

NPT Hydraulic Fittings

2. Installation Procedure

1. Wrap Sealing Tape: Wrap the tape clockwise (in the same direction as the threads), covering the root of the threads to the second tooth;

2. Manually Pre-Tighten: Screw the fitting into the port and manually tighten until resistance is noticeable;

3. Tooling Tighten: Use an open-end wrench and continue to rotate for 1.52 turns (or torque control, e.g., 1/2″ NPT requires 3545 N-m);

4. Pressure Test: Apply 1.25 times the working pressure of the fluid. 4. Pressure Test: Apply fluid at 1.25 times working pressure and hold pressure for 10 minutes without leakage.

Proper Installation of NPT Threads

3. Caution

Avoid over-tightening: prevent thread deformation or cracking (stainless steel is particularly sensitive);

Prohibit mixing standards: NPT and BSPP/BSPT threads are incompatible, forcing the installation will lead to leakage;

Regular inspection: check the sealing status every 3 months, and replace the deteriorated sealing material in a timely manner.

Do not confuse NPT threads with NPTF threads, the full name of NPTF is National Pipe Taper Fuel, which is dry seal tapered threads in Chinese. Although NPT and NPTF threads are similar in appearance, they do not form a leak-tight seal in the same way; NPT threads have a small gap between the root and the top of the thread, which creates a spiral leak path along the top of the male thread. A thread sealant is required to prevent leakage. NPTF threads, on the other hand, require no sealant and are less prone to leakage.

NPT hydraulic fittings are the “lingua franca” of American Standard hydraulics, and proper selection and installation can significantly improve system reliability. In high temperature, corrosion and other severe conditions, we recommend that the preferred choice is 316L stainless steel NPTF fittings and refer to ASME B16.11 pressure test standards. If you need to adapt to complex scenarios (such as ultra-high pressure), you can consult our engineers free of charge.

(Special customization available, free samples)

China Huiqi (Beijing) Technology Co., Ltd, with fifteen years of excellence, is a professional manufacturer of high quality hydraulic hose fittings, hydraulic hose couplings, hydraulic hose fittings, hydraulic adapters and hydraulic fittings. We offer a wide range of products, including thousands of unique types and sizes of hydraulic fittings, and our comprehensive solutions meet the needs of different industries, ensuring reliable performance and adaptability to a wide range of job requirements.

Our modern manufacturing facility is equipped with 16 automatic CNC lathes and supported by 75 experienced technicians to ensure high precision and consistency in every hydraulic fitting.

Our factory-professional sales team of more than 10 professionals is dedicated to providing exceptional customer service and support. From consultation to post-sale assistance, our team ensures seamless communication, customized solutions and timely responses to meet your unique needs.

What are the main types of our hydraulic fittings:

1, Rings, matching with many kinds of pipes, such as SAE, DIN, EN, GB, etc.

Flat seal fittings, multi-seal fittings, spherical seal fittings, 60°taper seal fittings, 74°taper seal fittings, 24°taper O-ring L.T. fittings, 24°taper O-ring H.T. fittings, JIS 60°taper seal fittings, riser fittings, Japanese metric fittings, etc.;3, British style pipe fittings

3,British style pipe fittings

JIS BSP 60°taper sealing fittings, BSPT fittings, BSP multi-seal fittings, BSP flat sealing fittings, BSP O-ring sealing fittings

4,U.S. Pipe Fitting

NPT nipple, JIC 74°taper sealing nipple, NPSM 60°taper sealing nipple, ORFS flat sealing nipple, SAE O-ring sealing nipple

5, One Piece Fittings

JIC, BSP, Metric, Flange

6, Flange

SAE Code 62 Flanges, SAE Code 61 Flanges, CAT Flanges

Click below to get a free consultation with a technical engineer on WhatsApp!

Add engineer number 86 13311237753 directly on Whatsapp to connect online.