MIP Meaning

MIP (Male Iron Pipe), or Male Iron Pipe Fittings, is a term commonly used in North American plumbing systems, usually referring to the NPT standard male threads (male threads), paired with FIP (Female Iron Pipe, female threads). The following are its core points:

MIP Definition and Structural Characteristics

Essential Properties:

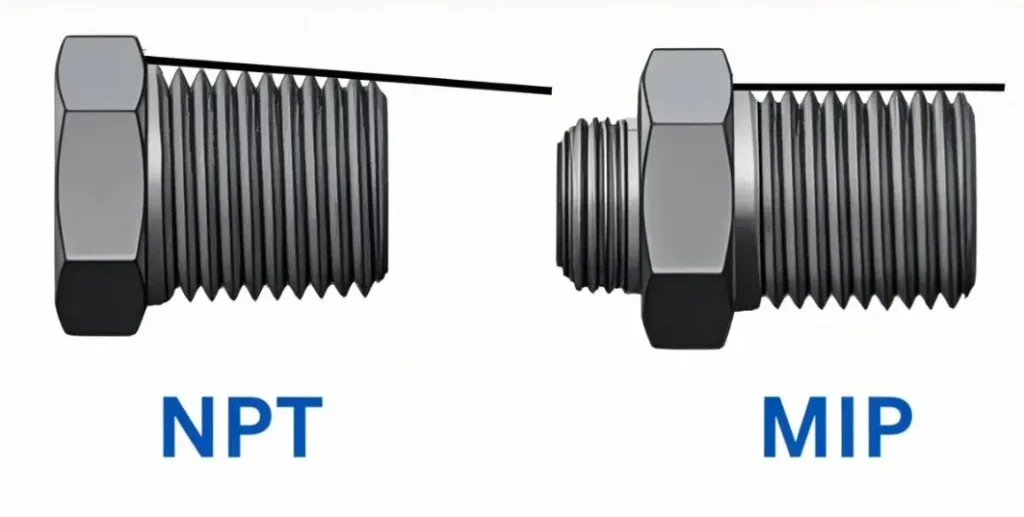

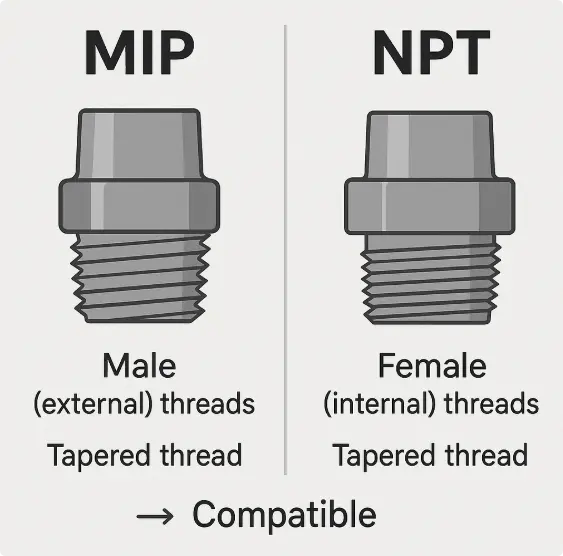

MIP is the generic name for NPT male threads, which are tapered (1:16 taper) and together with NPT female threads (FIP) form a sealing system.

Note: In non-North American regions, “MIP” may be incorrectly referred to as a straight thread (e.g. BSPP), and the actual standard needs to be judged in context.

Sealing Mechanism:

Relying on NPT tapered thread extrusion sealing, need to be used with raw material tape or sealant to fill the gap to prevent leakage.

Unlike straight threads (e.g. BSPP), MIP does not rely on a gasket seal.

NPT meaning

NPT (National Pipe Tapered Thread), or the U.S. National Tapered Pipe Thread, is a widely used standard for tapered pipe threads in North America, which is mainly used to realize hermetic connections in piping systems.

The following are its core points:

NPT Definition and structural features

Tapered design: Threads are tapered 1:16 (approximately 1/16 inch diameter reduction per inch of length) to form a mechanical seal through the tapered fit of the internal and external threads.

Sealing Mechanism: relies on tight extrusion between the threads, which needs to be matched with sealing materials (e.g., raw material tape, sealant) to fill the tiny gaps and prevent fluid or gas leakage.

Thread type:

Male Iron Pipe (MIP): Male end, usually labeled NPT.

Female Iron Pipe (FIP): Female end, used in conjunction with MIP.

MIP VS NPT Core Features and Uses

| Characteristics | NPT | MIP (as NPT male thread) | Straight threads (e.g. BSPP) |

| Thread Form | Tapered Thread (1:16 Taper) | Same as NPT (Tapered) | Parallel Thread (No Taper) |

| Sealing Mechanism | Tapered Thread Extrusion + Sealant | Same as NPT (Tapered) | Gasket or Flange Required |

| Scenarios | High-pressure fluids/gases (hydraulics, gas, chemical) | Pipe extensions, equipment interface connections | Low-pressure systems (water pipes, pneumatic equipment) |

| Main Standards | American Standard (ANSI/ASME B1.20.1) | Same as NPT (Tapered) | British Standard (BSPP), ISO Standard |

| Typical Applications | Industrial piping, oil well equipment, compressed air systems | Paired with FIP for piping systems | European appliances, automotive cooling systems |

MIP VS NPT Compatibility

MIP VS NPT Compatibility Analysis and Solution

The compatibility between MIP and NPT depends on the consistency of the thread standards of both. The following is a detailed analysis:

Core Conclusion

If MIP belongs to NPT standard:

Fully compatible, as MIP is essentially a male NPT thread, paired with a female NPT thread (FIP).

If MIP is mistaken for another standard (e.g. BSPP):

Incompatible, due to differences in thread shape, pitch, and angle that can lead to leakage or damage.

MIP VS NPT Compatibility Specific Scenario Analysis

Scenario 1: MIP (NPT male thread) and NPT female thread (FIP)

Compatibility: Fully compatible.

Description:

MIP is the male thread of NPT, which belongs to the same standard (American Standard ANSI/ASME B1.20.1) as the female NPT thread (FIP).

Both are sealed by taper thread extrusion + sealant, and need to wrap raw material tape or apply sealant during installation.

Scenario 2: MIP (NPT male thread) and straight thread (e.g. BSPP)

Compatibility: Incompatible.

Reason:

Different thread shapes: NPT is tapered (1:16 taper), BSPP is parallel threaded.

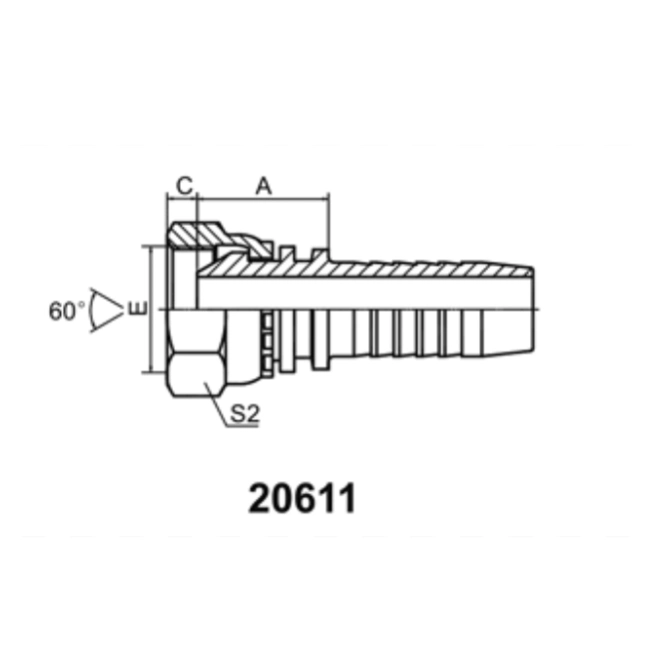

Different pitches and angles: NPT has a pitch of 11.5 teeth per inch and a thread angle of 60°; BSPP has a pitch of 11 teeth per inch and a thread angle of 55°.

Consequences of forced mixing: lead to thread damage, seal failure, and even joint cracking.

Scenario 3: MIP (mistaken for BSPP male threads) and NPT female threads

Compatibility: Incompatible.

Cause:

If MIP is actually BSPP (British Standard Parallel Thread), its parallel design cannot be matched with NPT’s tapered female thread, sealing pressure is concentrated locally, and it is easy to leak.

Compatibility Solution

If you need to connect different standard threads (e.g. NPT and BSPP), you need to solve the problem by the following ways:

- using an adapter:

For example: NPT to BSPP adapter (NPT thread on one end and BSPP thread on the other). - Choose a universal connector:

Some industrial fittings are designed to be multi-standard compatible (e.g., support both NPT and BSP), but need to be clearly labeled. - Rework the threads:

In non-critical scenarios, the thread standard can be modified by lathe, but there is a sealing risk, and it is not recommended for high pressure scenarios. - Critical considerations

- Define the thread standard:

Confirm type by measuring thread taper (1:16 for NPT), pitch and angle (60° for NPT).

Check the connector identification (e.g. NPT, BSPP). 2. - Forced installation is prohibited:

If there is an abnormal increase in resistance when screwing in, the threads may be mismatched, stop the operation immediately. - Differences in sealing methods:

NPT must use raw material tape or sealant;

Straight threads such as BSPP need to be matched with a washer.

MIP VS NPT Compatibility Summary

MIP and NPT compatibility premise: both belong to the same NPT standard (i.e. MIP for NPT male threads).

For cross-country projects or when mixing standards: conversion must be done via an adapter, otherwise leakage or damage will result.

Core principle: Always check the thread type before installation to avoid malfunctions due to name confusion (e.g. BSPP mistakenly called MIP).

MIP VS NPT sealing mechanism and installation method

NPT Sealing and Installation

Sealing steps:

1. Clean the thread surface;

2. Wrap 23 layers of raw tape (or apply sealant) in a clockwise direction;

3. Tighten until threads are fully seated to avoid cracking due to excessive force.

Advantages: High pressure sealing, anti-vibration.

Disadvantages: easy to leak after improper installation, need to re-seal after disassembly.MIP Straight Thread (e.g. BSPP) Sealing and Installation

Sealing steps:

1. Place a rubber/metal washer on the threaded end;

2. manually tighten and then reinforce with tools until the washer is slightly deformed (not excessive).

Advantages: simple installation, reusable.

Disadvantages: gaskets are prone to failure under high pressure and require regular maintenance.MIP VS NPT Advantages and Disadvantages Comparison

| Types | Advantages | Disadvantages |

| NPT | High-pressure sealing, vibration resistance, wide applicability | Dependent on sealant, high installation requirements, complex disassembly |

| MIP Straight Thread | Easy to install, reusable, gasket compatible | Low pressure limitations, gasket needs to be replaced due to ageing |

MIP VS NPT How to choose the right fitting?

- According to the application scenario:

High pressure fluid/gas: NPT is preferred.

Low pressure water/pneumatic system: Straight thread (such as BSPP) is more economical. - Regional standard:

North American projects: NPT/MIP; European/Asian projects: BSPP/BSPT. - Compatibility check:

Use a thread gauge to measure pitch and angle, or consult the supplier to clarify the standard.

Common Problems and Solutions

- Leakage problems

Cause: Insufficient sealant, deteriorated washers, incompatible threads.

Solution: NPT replenish raw material tape, replace washer for straight thread. - Thread damage

Cause: Mixing different standards or over-tightening.

Solution: Use a thread repair tool or replace the fitting. - Installation difficulties

Cause: Difficulty in initial seating of tapered threads.

Solution: Manually align and then rotate slowly to avoid oblique force.

MIP VS NPT Summary

NPT is preferred for high-pressure systems, but installation specifications need to be strictly followed;

MIP is used as a male NPT thread and needs to be paired with FIP;

Straight threads (BSPP) are suitable for low-pressure scenarios, relying on gasket sealing;

Core principle: Avoid mixing standards and select the appropriate solution based on pressure, region and application.

The risk of leakage and failure can be significantly reduced by correctly identifying the thread type, following the installation procedure and regular maintenance. If you have any other questions about NPT or MIP, you can contact our engineers in the first instance, and we will answer them for you free of charge.