Metric hydraulic fittings are key hydraulic components used in hydraulic systems to connect piping, valves, actuators (e.g., cylinders, motors) and other components, and their dimensions and thread specifications follow the Metric system (Metric) standard, which is widely used in Europe, Asia, and the global standardization of demanding industrial fields. Compared with the imperial (such as SAE, NPT) fittings, metric fittings in millimeters (mm), with uniform thread parameters and sealing form, suitable for high-pressure, high-precision needs of the hydraulic system.

1. Standardized design

Conforms to international standards (e.g. ISO 6149, ISO 8434) to ensure global universality.

– Thread type: Common metric threads include M thread (metric common thread) and metric taper thread (e.g. ISO 228-1).

– Seal forms: metal-to-metal seals, O-rings (e.g. ISO 1179) or flat seals (e.g. flange joints) are mostly used.

2. High pressure resistance

The working pressure ranges from 16MPa to 63MPa, and some high-pressure models can reach over 100MPa.

3. Material and Process

Material: carbon steel, stainless steel (e.g. 304/316), brass, etc., with high corrosion resistance.

Surface treatment: zinc plating, nickel plating, phosphating, etc., to enhance durability.

1. Metric threaded fittings (M series)

– Straight thread fittings: direct screwing connection through the thread, need to be matched with gasket or O-ring.

– Tapered thread fittings (e.g. ISO 8434-1): self-sealing using tapered threads, suitable for medium and high pressure systems.

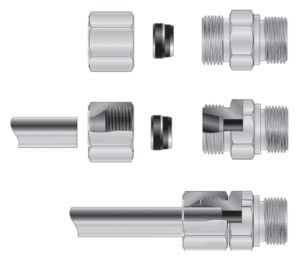

2. ferrule fittings (DIN 2353)

– It consists of fitting body, ferrule and nut, sealing is realized by pressing the pipeline through the ferrule, widely used in industrial equipments.

3. Flanged fittings

– The flange is fixed by bolts, suitable for high flow and high pressure system (such as hydraulic pipeline of construction machinery).

4. Quick-change couplings (ISO 16028)

– Allow rapid connection/disconnection, reduce fluid leakage, commonly used in applications requiring frequent disassembly.

5. Transition fittings

– Used for conversion between metric and imperial systems (e.g. M → NPT), to solve the compatibility problem of different standard interfaces.

1. ISO 6149: Standard for metric threaded ports and fittings, covering thread dimensions, sealing forms and test methods.

2. ISO 8434-1: 24° taper fitting (metric ferrule type) standard for high pressure systems.

3. DIN 2353: German Industrial Standard defining dimensional and performance requirements for ferrule fittings.

4.JIS B2351: Japanese Industrial Standard, similar to DIN 2353 but some parameters are different.

Metric 24° Taper Fitting Connection

DIN 2353

| DIN 2353 L Tube O.D.(mm) | DIN 2353 S Tube O.D. (mm) | Metric Thread Size | Male Thread O.D. (mm) | Female Thread I.D (mm) |

| 6 | M12 x 1.5 | 12 | 10.5 | |

| 8 | 6 | M14 x 1.5 | 14 | 12.5 |

| 10 | 8 | M16 x 1.5 | 16 | 14.5 |

| 12 | 10 | M18 x 1.5 | 18 | 16.5 |

| 12 | M20 x 1.5 | 20 | 18.5 | |

| 15 | 14 | M22 x 1.5 | 22 | 20.5 |

| 16 | M24 x 1.5 | 24 | 22.5 | |

| 18 | M26 x 1.5 | 26 | 24.5 | |

| 22 | 20 | M30 x 2.0 | 30 | 28 |

| 28 | 25 | M36 x 2.0 | 36 | 34 |

| 30 | M42 x 2.0 | 42 | 40 | |

| 35 | M45 x 2.0 | 45 | 43 | |

| 42 | 38 | M52 x 2.0 | 52 | 50 |

| Descriptive | Material | prices | Delivery time |

| One-Piece Fittings Metric Hydraulic Hose Fittings | Stainless Steel Carbon Steel | 0.10-1.99 USD/piece | 15-25 Days |

| Carbon Steel 2c9 Metric Threaded Bite Type Fittings | Carbon Steel | 0.10-10.00 USD/piece | 15-25 Days |

| Stainless Steel Metric Ferrule Fittings Hydraulic Rubber Hose Fittings | Carbon Steel Stainless Steel | 0.15-10.99 USD/piece | 15-25 Days |

| Stainless Steel Hydraulic Fittings 60 90 Degree Tapered Metric Fittings | Carbon Steel Stainless Steel | 0.10-15USD/piece | 15-25 Days |

| OEM O-Ring Metric 24 Degree Tapered Hydraulic Hose Fittings | Stainless Steel Carbon Steel | 0.15-10.99USD/piece | 15-25 Days |

| 20491 90 Metric Female 24 Tapered O-Ring LT Hydraulic Hose Fittings | Carbon Steel | 0.15-9.9 USD/piece | 15-25 Days |

1. Pressure level: select according to the maximum working pressure of the system (e.g. 25MPa, 40MPa). 2.

2. Temperature range: high temperature environment needs to choose stainless steel or special coating material.

3. Fluid compatibility: oil, water-based media or chemicals need to match the sealing material (such as NBR, FKM rubber).

4. Size matching: Confirm the pipeline outer diameter (OD) and thread specifications (such as M12 × 1.5, M16 × 1.5).

5. Installation space: Compact space can choose right angle or compact fittings.

1. Installation steps

– Clean the pipelines and fittings to avoid impurities into the system.

– For ferrule fittings, tighten the nut according to the standard torque to ensure the sealing of ferrule deformation.

– When using thread sealant or raw material tape, avoid blocking the flow path.

2. Common Problems

– Leakage: mostly due to damaged seals or untightened threads.

– Damaged threads: installation is not aligned, resulting in “misalignment”.

– Pressure drop: Improper fitting selection or internal clogging.

Metric hydraulic fittings have become a core component of modern hydraulic systems due to their standardization and high reliability. Correct selection and installation can significantly improve the efficiency and life of the system, and with the development of industrial intelligence, its design and function will continue to be optimized to meet the higher demand.

(Special customization available, free samples)

China Huiqi (Beijing) Technology Co., Ltd, with fifteen years of excellence, is a professional manufacturer of high quality hydraulic hose fittings, hydraulic hose couplings, hydraulic hose fittings, hydraulic adapters and hydraulic fittings. We offer a wide range of products, including thousands of unique types and sizes of hydraulic fittings, and our comprehensive solutions meet the needs of different industries, ensuring reliable performance and adaptability to a wide range of job requirements.

Our modern manufacturing facility is equipped with 16 automatic CNC lathes and supported by 75 experienced technicians to ensure high precision and consistency in every hydraulic fitting.

Our factory-professional sales team of more than 10 professionals is dedicated to providing exceptional customer service and support. From consultation to post-sale assistance, our team ensures seamless communication, customized solutions and timely responses to meet your unique needs.

What are the main types of our hydraulic fittings:

1, Rings, matching with many kinds of pipes, such as SAE, DIN, EN, GB, etc.

2, metric fittings

Flat seal fittings, multi-seal fittings, spherical seal fittings, 60°taper seal fittings, 74°taper seal fittings, 24°taper O-ring L.T. fittings, 24°taper O-ring H.T. fittings, JIS 60°taper seal fittings, riser fittings, Japanese metric fittings, etc.;3, British style pipe fittings

3,British style pipe fittings

JIS BSP 60°taper sealing fittings, BSPT fittings, BSP multi-seal fittings, BSP flat sealing fittings, BSP O-ring sealing fittings

4,U.S. Pipe Fitting

NPT nipple, JIC 74°taper sealing nipple, NPSM 60°taper sealing nipple, ORFS flat sealing nipple, SAE O-ring sealing nipple

5, One Piece Fittings

JIC, BSP, Metric, Flange

6, Flange

SAE Code 62 Flanges, SAE Code 61 Flanges, CAT Flanges

Click below to get a free consultation with a technical engineer on WhatsApp!

Add engineer number 86 13311237753 directly on Whatsapp to connect online.