JIC, NPT and BSP are three common thread/fitting standards used in hydraulics, pneumatics and plumbing. They each have different design features, sealing mechanisms and application scenarios.

How to choose the right thread standard is crucial to the sealing, compatibility and reliability of the system. In this article, we will introduce their differences, sealing, applications, installation methods and common problems in detail.

JIC Meaning (Joint Industry Council)

Standard: SAE J514 (Society of Automotive Engineers standard)

Type: 37° tapered seating surface (flare fitting)

Sealing method: Metal-to-metal taper seal

Main applications: Hydraulic systems (e.g. construction machinery, agricultural equipment, aerospace)

NPT Meaning (National Pipe Taper)

Standard: ANSI/ASME B1.20.1 (American National Standard)

Type: Tapered Thread

Sealing method: Thread fit + sealant/raw tape

Main applications: Piping, pneumatic systems, water/oil/gas transportation in North America.

BSP Meaning (British Standard Pipe)

Standard:

BSPP (G series): Parallel straight thread (British Standard Pipe Parallel)

BSPT (R series): Tapered thread (British Standard Pipe Tapered)

Sealing method:

BSPP: Sealing by gasket or O-ring.

BSPT: sealing by thread taper (similar to NPT)

Main applications: Hydraulic, pneumatic and piping systems in Europe, Asia, etc.

JIC vs NPT vs BSP Threads Main Differences Comparison

| Characteristics | JIC (37° Flare) | NPT (Tapered) | BSPP (G) | BSPT (R) |

| Thread Type | Non-Threaded (Against Taper) | Tapered | Parallel | Tapered |

| Sealing Method | Metal Taper Compression | Threaded + Sealant | Gasket/O-Ring | Threaded + Sealant |

| Thread Angle | 37° Tapered | 60° Threaded | 55° Threaded | 55° Threaded |

| Common sizes | 1/8“ 2” | 1/16“ 4” | 1/8“ 6” | 1/8“ 6” |

| Applicable Regions | Global (AFSL) | North America | Europe/Asia | Europe/Asia |

| Sealant Required | Not Required | Required | Required (BSPP) | Required (BSPT) |

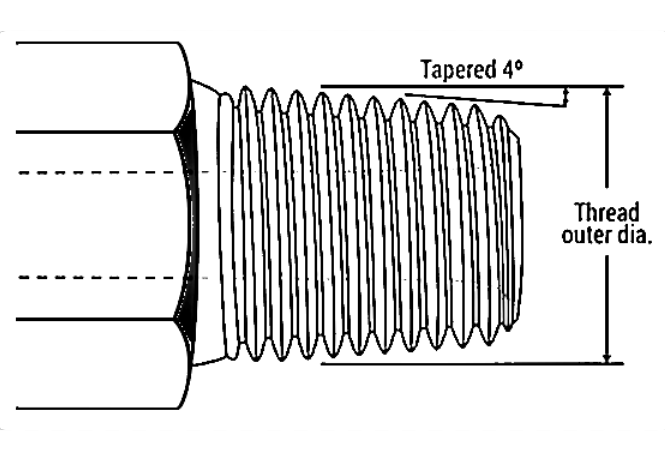

JIC Thread Diagram

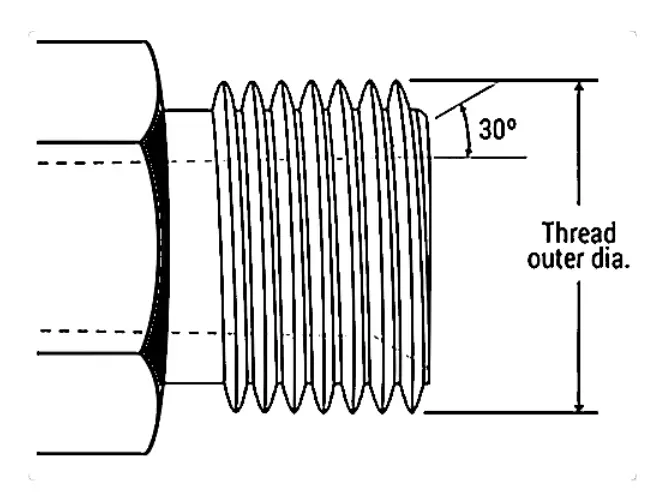

BSPP Thread Diagram

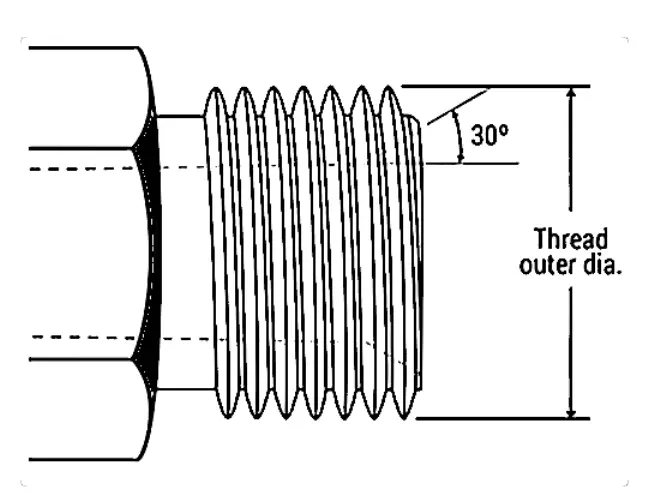

BSPT Thread Diagram

How to quickly differentiate between JIC, NPT and BSP threads with the naked eye or tools?

Naked eye observation method (no tools required)

Observe the shape of the joint

JIC (37° Flare) Feature:

37° internal taper at the end of the fitting (for metal-to-metal sealing)

Hexagonal nut on the outside for fastening

No threaded sealing surface (completely different from NPT/BSP)

NPT (tapered thread) characteristics:

Threads have a pronounced taper (progressively thicker from the end to the root).

Sharp thread profile (60° tooth angle)

Often requires packing tape or sealant.

BSP (BSPP/BSPT) Characteristics:

BSPP (G series): Straight thread (no taper), usually with a sealing washer groove on the end

BSPT (R series): tapered thread (similar to NPT, but with more rounded teeth, 55° tooth angle)

Tool Measurement (more accurate)

Using a Thread Gauge

-NPT: 60° tooth angle, measured with NPT gauge.

-BSP: 55° tooth angle, measured with a BSP gauge.

-JIC: No thread, only 37° taper angle can be measured.

Caliper Measurement Method

Measure the outer diameter (OD) and pitch (TPI) of threads:

NPT: Standard sizes such as 1/8″-27 (OD approx. 9.7mm, 27 teeth/inch)

BSPP: 1/8″-28 (OD approx. 9.7mm, 28 teeth/inch)

BSPT: 1/8″-28 (tapered, root thicker than end)

Note: NPT and BSP have close 1/8” dimensions but different tooth angles (60° vs 55°).

Taper Test

NPT/BSPT: tapered threads that get tighter as they are screwed in.

BSPP: Straight threads, even resistance when screwed in.

JIC vs NPT vs BSP Threads Application Scenarios and Analysis of Advantages and Disadvantages

JIC (37° Flare)

Advantages:

Good high pressure sealing (for 3000+ PSI hydraulic system)

Repeatable disassembly, not easily damaged

No sealant required, reducing risk of leakage

Disadvantages:

Higher cost

Requires specialized tools for installation (e.g. flaring tools)

Typical applications: construction machinery, aviation hydraulic systems, high-pressure oil pipes

NPT (Tapered Thread)

Pros:

Common to North America, easy to source

Self-sealing (tapered threads get tighter as you tighten them)

Disadvantages:

Requires raw tape or sealant, otherwise prone to leakage

Threads wear out after multiple disassemblies

Typical uses: water pipes, gas pipes, industrial pipes

BSP (BSPP / BSPT)

Advantages:

Europe / Asia common, good international compatibility

BSPP can be used with gaskets for reliable sealing.

BSPT is similar to NPT, but with finer threads

Disadvantages:

Difficult to source for North American market

BSPP requires additional seals

Typical uses: hydraulic equipment (European brands), pneumatic fittings, water pipes

JIC vs NPT vs BSP Compatibility and Interchangeability

JIC is not compatible with BSP / NPT (completely different designs).

NPT and BSPT are not directly interchangeable (different thread angles, NPT 60° vs BSPT 55°).

BSPP (G) and BSPT (R) are not interchangeable (one parallel, one tapered).

Adaptation program:

Use an adapter (e.g. NPT→BSP adapter).

Avoid forcing in as this may damage the threads.

JIC vs NPT vs BSP Mounting Methods

JIC Installation

- Use a flaring tool to make a 37° taper. 2.

- Tighten the nut with a torque wrench to ensure that the metal taper fits.

NPT Installation

- Wrap packing tape or apply sealant (clockwise). 2.

- Hand tighten and then turn 12 turns with a wrench (avoid over tightening which may cause cracking).

BSPP / BSPT Installation

BSPP: Add washers or O-rings, then tighten.

BSPT: Similar to NPT, requires sealant.

JIC vs NPT vs BSP Frequently Asked Questions and Solutions

Are NPT and BSP interchangeable?

No, the thread angle is different (NPT 60° vs BSP 55°) and forcing the fitting will result in leakage or thread damage.

Why do NPT fittings always leak?

Possible reasons:

Insufficient wrapping of the biotape

Worn threads (after several disassemblies)

Improper tightening force

How to distinguish between BSPP and BSPT?

BSPP (G): Straight thread, requires gasket sealing.

BSPT (R): Tapered thread, similar to NPT.

Can JIC fittings directly replace BSPP?

No, an adapter must be used.

Conclusion

JIC is suitable for high-pressure hydraulic systems and provides a reliable seal at a high cost.

NPT is preferred for North American piping, but requires sealant.

BSP is more common in Europe/Asia, BSPP requires a gasket, BSPT is similar to NPT.

Do not mix as this can lead to leaks or damage, use adapters if necessary.

Choosing the right thread standard can significantly reduce the risk of leakage and improve system reliability. If you have any other technical questions about JIC vs NPT vs BSP, you can directly contact our technical engineers, who will answer your questions for free.