JIC hydraulic fittings in-depth analysis: from aerospace technology to the construction machinery of the whole scene application guide

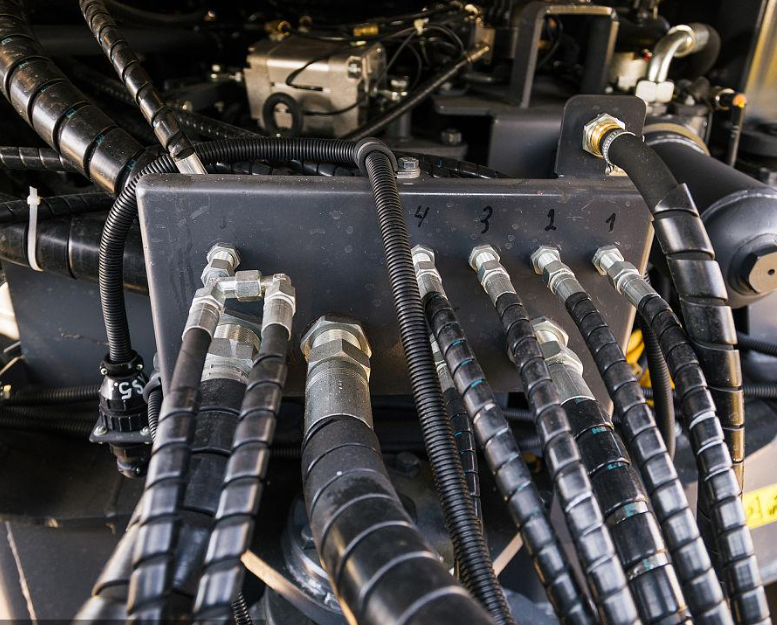

Introduction: the neglected “blood vessel connector”.

(Figure 1: Scene of construction machinery with oil leakage in the hydraulic system)

The O&M report of a wind farm in 2022 shows that the downtime loss due to hydraulic connector failure accounts for 42% of the total maintenance cost. And projects using the JIC standard have extended the first failure cycle to 8,000 hours – the engineering miracle of the 37° metal taper seal.

I. The structural mystery of JIC Hydraulic fittings

1.1 Civilian evolution of WWII military pedigree

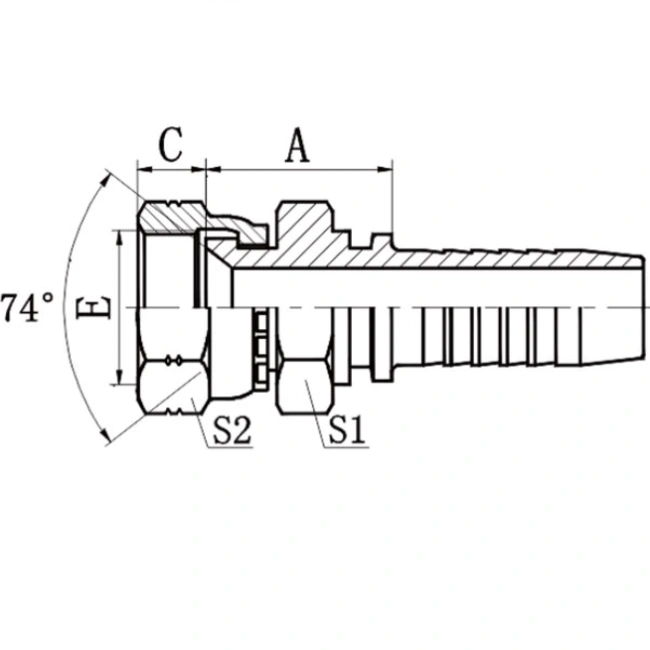

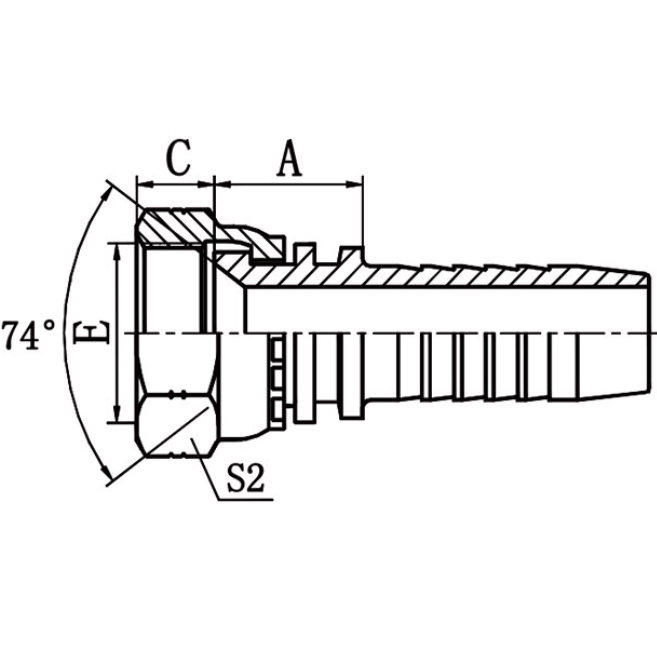

Core design: 37° double taper occlusion structure

Military standard: originated from U.S. military standard MIL-F-18866, now transformed into SAE J514.

Chineseization process: GB/T 2878-2023 is equivalent to the latest international standards.

1.2 Physical sealing principle

| Seal Type | Principle | Applicable Pressure |

| JIC Taper | Plastic deformation of metals | ≤100MPa |

| NPT thread | Threaded interference seals | ≤40MPa |

| O-ring | Elastomer Compression | ≤70MPa |

Experimental data: under 10Hz vibration environment, the leakage of JIC Hydraulic fittings is only 1/8 of NPT hydraulic fittings (Hydraulic Laboratory of Tsinghua University, 2023)

II. Made-in-China Scenario Practical Manual

2.1 Application in the field of construction machinery

XCMG Case:

Problem: Seal failure due to temperature difference under plateau working conditions

Solution: Adopt nickel-plated JIC Hydraulic fittings + PTFE coating

Effect: Maintenance cycle of loader on Qinghai-Tibet line increased from 200h to 1500h.

2.2 Breakthrough in New Energy Industry

| Material (that sth is made of) | Temperature Range | Resistant to electrolyte corrosion | Cost Factor |

| 304 Stainless steel | -50~400℃ | ★★☆ | 1.2 |

| Aluminum Alloy | -200~600℃ | ★★★★★ | 4.5 |

| Ceramic Composite | -100~800℃ | ★★★★☆ | 6.8 |

Ningde Times practice: the use of aluminum-plated titanium alloy JIC, so that the electrode roller press hydraulic system failure rate decreased by 81 percent

III. Fatal Details of Installation and Maintenance

3.1 Common Mistakes of Chinese Engineers

Typical mistakes:

- Using an adjustable wrench leads to wear of the hexagonal surface

- Failure to use angle gauge to assist tightening

- Reusing old fittings more than 3 times

3.2 New Method of Intelligent Installation

Zoomlion solution: real-time guidance for installation through AR glasses, increasing the qualification rate of new hires from 58% to 92

IV. Three-dimensional matrix for procurement decision-making

4.1 Key indicators for national production substitution

| Brand Type | Price Range | life expectancy index | After-sales response |

| Imported high-end | 800~2000 | 1.8 | 48hourly |

| National quality | 300~800 | 1.5 | 24hourly |

| Low-end imitation | 50~200 | 0.7 | insecurity |

Sany supply chain data: domestic JIC hydraulic fittings procurement share increased from 32% in 2018 to 78% in 2023

V. Future technology frontiers

5.1 Intelligent sensing joints

Real-time monitoring: pressure, temperature, vibration three parameters

Huawei’s 5G application case: realizing predictive maintenance of hydraulic system in Xiongan underground pipeline corridor

5.2 Green Remanufacturing Technology

Xiamen remanufacturing program:

Nano Spraying Repair of Tapered Surface

Life recovery rate up to 85% of new products

Cost reduced by 60%.

The mission of small joints for national heavy equipment

“In the landing gear hydraulic system of the C919 large airplane, 217 JIC Hydraulic fittings withstood the extreme test of minus 50°C – this is not only a technological victory, but also a testimony to the precision of Chinese manufacturing.”