JIC stands for Joint Industry Conference, a standard developed and promoted by the American Society of Mechanical Engineers (SAE) and other organizations.JIC hydraulic fittings follow this standard and have a uniform design and specifications that make fittings from different manufacturers interchangeable.

The JIC in JIC Fittings stands for Joint Industry Council and refers specifically to a standard for hydraulic fittings developed by the Society of Automotive Engineers (SAE) for use in high-pressure hydraulic systems. Its core meaning is:

JIC Fittings Standard Definition

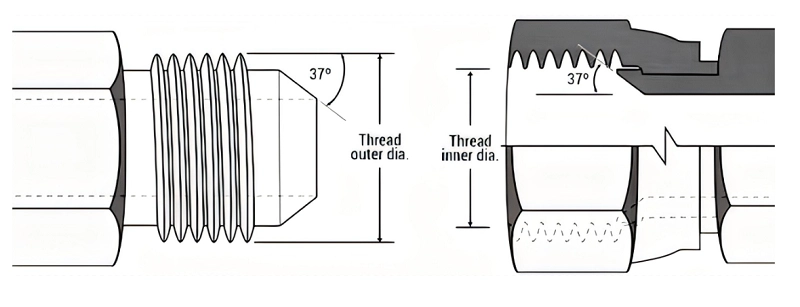

Adopting 37 degree conical flare seal (metal-to-metal contact), sealing is realized by taper pressing, suitable for high-pressure environment (e.g. construction machinery, aviation hydraulic system).

JIC Fittings Key Markings

Conforms to SAE-J514.

Fitting sizes are labeled **JIC + size** (e.g. `JIC 1/2″`).

The core design of the Jupiter Hydraulic Fitting is its 37 degree tapered sealing surface. This design allows the tapered surface to fit snugly when the fitting is tightened, creating a metal-to-metal seal. The other end of the fitting is usually threaded and is used to connect hydraulic lines or other equipment.JIC fittings are typically made of carbon steel, stainless steel or brass to suit different operating environments and pressure requirements.

JIC hydraulic fittings are available in a variety of types, including straight fittings, elbows, tees, crosses, etc. to meet the needs of different piping layouts. Fitting specifications are typically categorized by pipe diameter and thread size, with common pipe diameters ranging from 1/8 inch to 2 inches, and thread types including NPT (U.S. Standard Tapered Pipe Thread) and BSP (British Standard Pipe Thread).

JIC 37° Flare (SAE J514)

JIC Fittings 37° (SAE J514)

| Inch size | Dash size | Thread Size | Male Thread O.D. (in) | Female thread O.D (in) | ||

| 1⁄8 | -2 | 5⁄16 – 24 | 5⁄16 | 0.31 | 9⁄32 | 0.27 |

| 3⁄16 | -3 | 3⁄8 – 24 | 3⁄8 | 0.38 | 11⁄32 | 0.34 |

| 1⁄4 | -4 | 7⁄16 – 20 | 7⁄16 | 0.44 | 13⁄32 | 0.39 |

| 5⁄16 | -5 | 1⁄2 – 20 | 1⁄2 | 0.5 | 15⁄32 | 0.45 |

| 3⁄8 | -6 | 9⁄16 – 18 | 9⁄16 | 0.56 | 17⁄32 | 0.51 |

| 1⁄2 | -8 | 3⁄4 – 16 | 3⁄4 | 0.75 | 11⁄16 | 0.69 |

| 5⁄8 | -10 | 7⁄8 – 14 | 7⁄8 | 0.88 | 13⁄16 | 0.81 |

| 3⁄4 | -12 | 1 1⁄16 – 12 | 11⁄16 | 1.06 | 1 | 0.98 |

| 7⁄8 | -14 | 1 3⁄16 – 12 | 1 3⁄16 | 1.19 | 1 1⁄8 | 1.1 |

| 1 | -16 | 1 5⁄16-12 | 1 5⁄16 | 1.31 | 1 1⁄4 | 1.23 |

| 1 1⁄4 | -20 | 1 5⁄8 – 12 | 1 5⁄8 | 1.63 | 1 9⁄16 | 1.54 |

| 1 1⁄2 | -24 | 1 7⁄8 – 12 | 1 7⁄8 | 1.88 | 1 13⁄16 | 1.79 |

| 2 | -32 | 2 1⁄2 – 12 | 2 1⁄2 | 2.5 | 2 7⁄16 | 2.42 |

| Descriptive | Material | prices | Delivery time |

| Parker 43 Series JIC 37 Degree Hydraulic One-Piece Crimp Fittings | Carbon Steel Stainless Steel | 0.75-15.9 USD/piece | 15-25 Days |

| OEM JIC Stainless Steel Hydraulic Hose Fittings | Stainless Steel | 0.25-9.9 USD/piece | 15-25 Days |

| 90 Degree Elbow JIC Carbon Steel Fittings 1D9 Swivel Hydraulic Union | Carbon Steel | 0.25-11.99 USD/piece | 15-25 Days |

| New Carbon Steel 90 Degree Elbow Hydraulic Female Threaded Hose JIC Fitting 26791 | Carbon Steel | 0.50-9.9USD/piece | 15-25 Days |

| 3/8” Straight JIC Female Stainless Steel Hydraulic Fittings | Stainless Steel | 0.45-9.9 USD/piece | 15-25 Days |

| 20411 20441 20491 Jic Reusable Hydraulic Hose Fittings Metric Swivel Hydraulic Hose Crimp Fittings | Carbon Steel | 0.45-6.6 USD/piece | 15-25 Days |

JIC hydraulic fittings are widely used in engineering machinery, agricultural machinery, ships, petrochemical, aerospace and other fields. In these fields, JIC couplings can withstand high pressure and harsh working environments to ensure the stable operation of hydraulic systems.

When installing JIC hydraulic fittings, you first need to make sure that the tapered surface of the fitting and the tapered surface of the connector are clean and undamaged. Then, align the coupling with the connector, tighten the threads by hand, and finally tighten with a wrench at the specified torque value. Care should be taken not to over-tighten during installation to avoid damage to the sealing surfaces.

The advantages of JIC hydraulic fittings are high

Reliability: 37 degree tapered sealing surface design ensures good sealing performance.

Easy to install: simple structural design makes the installation process fast and convenient.

Wide applicability: a variety of types and specifications of joints to meet different application requirements.

Higher cost: JIC fittings are more expensive than other types of hydraulic fittings.

Higher weight: Metal fittings are heavier as compared to plastic fittings, which may increase the total weight of the system.

JIC hydraulic fittings play an important role in hydraulic systems due to their excellent sealing properties and wide range of applications. Despite certain cost and weight disadvantages, their high reliability and ease of installation make them the connector of choice for many industrial applications. With advances in materials science and manufacturing technology, future JIC hydraulic fittings are expected to offer a better balance of performance and cost.JIC stands for Joint Industry Conference, a standard developed and promoted by the American Society of Mechanical Engineers (SAE) and other organizations.JIC hydraulic fittings adhere to this standard and have a uniform design and specifications that make fittings from different manufacturers interchangeable.

How to measure JIC hydraulic fittings?

Do I need raw tape or sealant for JIC fitting installation?

No.

JIC fittings utilize a 37° metal taper seal that relies on two tapers being pressed together to achieve a seal.

❌ The use of raw tape or sealant is prohibited (may cause debris to enter the hydraulic system).

✅ A small amount of hydraulic fluid may be applied to reduce friction and facilitate tightening.

Common causes of JIC fitting leakage and solutions?

1. Scored or worn sealing surface → Replace with new fitting.

2. Threads not aligned → Reinstall to ensure parallel entry.

3. Deformation caused by over-tightening → Reinstall at standard torque.

4. Hydraulic oil contamination → Clean the system and replace the filter element.

Solution:

For minor leaks try retightening (not exceeding the recommended torque).

Severe leaks require replacement of the fitting or use of a seal repair kit.

Are JIC fittings interchangeable with other standards?

NPT ❌ Not compatible ❌ NPT is a tapered thread seal, JIC is a tapered seal, mixing will result in leakage.

BSPP ❌ Not compatible, imperial parallel threads, conversion fittings required.

ORFS ❌ Incompatible, flat seal structure is different.

SAE 45° ⚠️ emergency available , similar but different angle, may leak.

Solution:

Use JIC to NPT or JIC to BSPP adapters.

(Special customization available, free samples)

China Huiqi (Beijing) Technology Co., Ltd, with fifteen years of excellence, is a professional manufacturer of high quality hydraulic hose fittings, hydraulic hose couplings, hydraulic hose fittings, hydraulic adapters and hydraulic fittings. We offer a wide range of products, including thousands of unique types and sizes of hydraulic fittings, and our comprehensive solutions meet the needs of different industries, ensuring reliable performance and adaptability to a wide range of job requirements.

Our modern manufacturing facility is equipped with 16 automatic CNC lathes and supported by 75 experienced technicians to ensure high precision and consistency in every hydraulic fitting.

Our factory-professional sales team of more than 10 professionals is dedicated to providing exceptional customer service and support. From consultation to post-sale assistance, our team ensures seamless communication, customized solutions and timely responses to meet your unique needs.

What are the main types of our hydraulic fittings:

1, Rings, matching with many kinds of pipes, such as SAE, DIN, EN, GB, etc.

Flat seal fittings, multi-seal fittings, spherical seal fittings, 60°taper seal fittings, 74°taper seal fittings, 24°taper O-ring L.T. fittings, 24°taper O-ring H.T. fittings, JIS 60°taper seal fittings, riser fittings, Japanese metric fittings, etc.;3, British style pipe fittings

3,British style pipe fittings

JIS BSP 60°taper sealing fittings, BSPT fittings, BSP multi-seal fittings, BSP flat sealing fittings, BSP O-ring sealing fittings

4,U.S. Pipe Fitting

NPT nipple, JIC 74°taper sealing nipple, NPSM 60°taper sealing nipple, ORFS flat sealing nipple, SAE O-ring sealing nipple

5, One Piece Fittings

JIC, BSP, Metric, Flange

6, Flange

SAE Code 62 Flanges, SAE Code 61 Flanges, CAT Flanges

Click below to get a free consultation with a technical engineer on WhatsApp!

Add engineer number 86 13311237753 directly on Whatsapp to connect online.