JIC and NPT fittings are two of the most commonly used connections in hydraulic systems, but engineers and technicians often encounter a variety of problems during actual use. This article will summarize the common problems of JIC and NPT fittings and provide solutions to help you avoid installation errors, leaks and system failures.

JIC fittings common problems:

What if a JIC fitting is leaking?

Possible causes:

Damaged or scratched 37° taper

Substandard flare (incorrect angle)

Nut not tightened or overtightened causing deformation

Solution:

Check the sealing surface and replace the fitting if damaged

Re-create the 37° taper using a special flaring tool

Tighten to standard torque (avoid over tightening or over loosening)

Can JIC couplings be reused?

Yes, provided the following conditions are met:

the sealing surfaces are not visibly worn or deformed

the fitting is clean and free from contaminants that could affect the sealing.

It is not recommended to dismantle the same fitting more than once, and it is recommended to replace it for long term use.

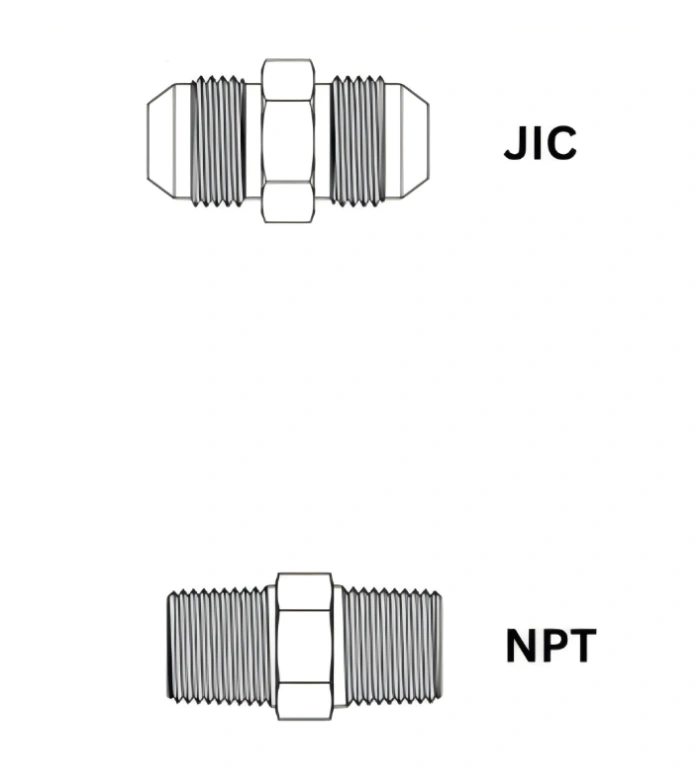

Are JIC fittings interchangeable with NPT fittings?

No, they are not directly interchangeable, but can be made compatible by means of an adapter (JIC to NPT).

Note: Pressure ratings may be reduced after conversion, so select according to system requirements.

Is the JIC fitting still leaking after installation?

Check the steps:

- Make sure the fitting size matches (e.g. 1/2“ JIC cannot be mixed with 9/16”).

- Check that the flare angle is 37° (incorrect angle will result in a poor seal). 3. Check that the wall thickness is correct.

- Check that the wall thickness is in accordance with the standard (too thin may result in flare rupture).

Frequently asked questions about NPT fittings:

What about leakage at the threads of NPT fittings?

Possible causes:

Threads not properly sealed (insufficient raw tape or sealant)

Damaged threads (slipped or worn)

Taper mismatch (e.g. BSPT mistakenly fitted with NPT)

Solution:

Disassemble and rewind raw tape or apply sealant (e.g. PTFE adhesive)

Replace damaged fittings

Ensure correct NPT thread is used (not BSPP/BSPT)

Can NPT fittings be reused?

Yes, but care should be taken:

Raw tape or sealant needs to be rewound or applied after each disassembly

The threads may be worn out after several disassemblies.

Is the NPT fitting not tight or over-tightened?

Reason:

NPT is a tapered thread, over-tightening can cause cracking of the fitting.

Friction is too high due to incorrect use of sealing material.

Correct installation method:

- hand tighten 23 turns to ensure thread alignment

- Turn 11.5 turns with a wrench (do not exceed 2 turns)

- Check for leaks and fine-tune if necessary.

Can NPT fittings withstand high pressures?

NPT is generally suitable for low pressure (<3000 PSI), JIC or ORFS fittings are recommended for high pressure environments.

If NPT must be used, it is recommended that thicker wall fittings be used with stronger seals (e.g., threadlocker).

JIC vs NPT Frequently Asked Questions:

Which is better, JIC or NPT?

JIC advantage: high pressure resistance, reliable sealing, anti-vibration, suitable for construction machinery, aerospace.

NPT advantage: low cost, simple installation, suitable for water, pneumatic and low pressure hydraulic systems.

Selection basis: according to the pressure, medium, budget decision.

Can JIC and NPT be connected directly?

Can not be directly connected, need to use the conversion connector (such as JIC female to NPT male thread).

Note: After conversion, the system pressure cannot exceed the tolerance range of NPT.

Are the dimensions of JIC and NPT easily confused?

It is easy to confuse, for example:

1/2“ JIC ≠ 1/2” NPT (different threads)

1/4“ JIC (UNF thread) is not compatible with 1/4” NPT (NPT thread).

Solution: Use a thread gauge or consult a size comparison chart.

Installation and Maintenance FAQ:

Do I need special tools to install JIC fittings?

Required:

Flaring tool (to make a 37° taper)

Torque wrench (to ensure correct tightening torque)

Can I seal NPT fittings with both raw tape and sealant?

Yes, but it is not recommended:

Raw material tapes (PTFE) are suitable for general sealing.

Sealants (e.g. Loctite 545) are suitable for high temperature and high pressure environments.

Avoid mixing them, as it may lead to overfilling and affect the thread bite.

How to prevent “cold flow” leaks in NPT fittings?

Cold Flow: Sealing material deforms under pressure, resulting in leakage.

Solution:

Use high quality PTFE tape

Change to a metal-sealed fitting (e.g. JIC)

Industry Application Question:

Can I use NPT fittings in excavator hydraulic systems?

Not recommended: Excavators are high pressure systems (3000+ PSI) and NPT is prone to leakage, JIC or ORFS fittings should be used.

Can NPT fittings be used for fuel systems?

Yes, but with care:

Fuel is permeable and a fuel-specific sealant should be used.

JIC or AN fittings are recommended (safer).

In summary: How to avoid common problems?

- Choose the right type of fitting (JIC for high pressure, NPT for low pressure).

- Use proper tools for installation (JIC needs flaring tool, NPT needs raw material tape).

- Regular inspection and maintenance to prevent leakage and thread wear. 4.

- Avoid mixing standards (e.g. JIC and NPT are not directly compatible).

If you still have questions, we recommend consulting our factory professional engineers, who can answer your questions for free!