In hydraulic and fluid power systems, where reliable, leak-free connections are essential, JIC 37° Flare-Off Fittings have become one of the most trusted standards for hydraulic fittings around the world, thanks to their proven design, excellent sealing performance, and wide range of applicability. In this article, We will delve into the meaning of the standard, the different types, parameters, selection, application, and installation from different perspectives.

JIC 37° Flare Fittings Meaning Standard

Core Standard: Based on SAE J514 standard.

Key feature: metal-to-metal hard seal with 37° inner taper (inside the coupling nut) and 37° outer taper (tube flare end).

SEALING PRINCIPLE: When the coupling nut is tightened, the two 37° tapers fit tightly together to form a high-pressure sealing band. No additional sealing washers are required.

History and Popularity: Promoted by the Joint Industry Council, “JIC” has become synonymous with the standard and is widely used in North American and global industry.

Note: “JIC” is more commonly used as a generic term, but strictly follows the current SAE J514 standard

Main types of JIC 37° flare fittings: by functional configuration

Straight Fittings.

Description: This is the most basic form. This is the basic form. The body of the fitting is a straight tube with a JIC 37° flare at both ends (female thread with a 37° female taper or male thread with a 37° male taper).

Function: To connect two rigid pipes or hoses with the same or different threaded ports (but both with JIC 37° flare), to realize straight line extensions or to change the type of ports (e.g. female JIC on one end, male JIC on the other).

Common forms: female JIC on both ends; male JIC on both ends; female JIC on one end + male JIC on the other (also known as “male/female straight-through” or “male/female straight-through”).

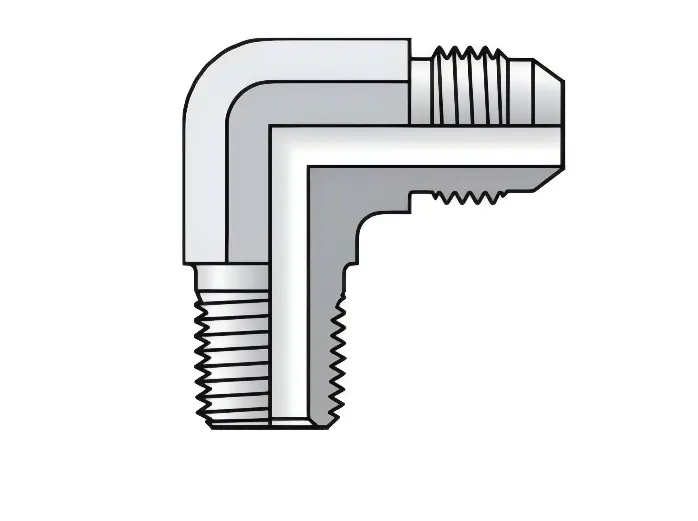

90° Elbow Fitting.

Description: The body of the fitting is bent at a right angle of 90 degrees. The two connections are located perpendicular to each other, and each connection is a JIC 37° flare.

Function: Used to change the direction of piping by 90 degrees to save space or to bypass obstacles. Also available in port combinations (inside-out, inside-in, outside-out).

Key feature: Corners are usually smooth and rounded to minimize flow resistance and stress concentrations. There are “short elbows” and “long elbows”, the latter having a larger bend radius and less resistance to flow for higher flow rates or where a smoother turn is required.

45° Elbow Fitting.

Description: The body of the fitting is bent at a 45° angle. The axes of the two fittings are bent at a 45-degree angle.

Function: Used to change the direction of piping by 45 degrees. Provides a smoother turn than a 90° elbow.

Application: Commonly used when a smaller angle of turn is required or when space constraints do not allow the use of a 90° elbow.

Tee Fitting.

Description: The body of the fitting is in the shape of a “T” or “cross” with three connections. Normally one connection (branch) is at 90° to the other two connections (main). All connections are JIC 37° flare connections.

Function: Used to separate a branch from a main line to divert or combine fluids.

Common forms.

Equal Tee: Three connections of the same size.

Reducing Tee: Branch port size is different from main port size (e.g., 1/2“ JIC on main, 3/8” JIC on branch).

Port combinations: The three ports can be any combination of female and male threads (e.g., female inside, female inside, male outside, etc.).

Reducing Fittings.

Description: Fitting body is straight through, but with different sized JIC 37° flare ports at each end.

Function: Used to connect two different sized hard or soft tubes (e.g., 3/4“ tube to 1/2” tube).

Common forms: female on both ends (different sizes); male on both ends (different sizes); female on one end + male on the other (different sizes).

Plugs/Screw Plugs.

Description: Plugs with only one JIC 37° flare end (usually male with 37° taper) and a closed hex head or socket head on the other end.

Function: Used to permanently or temporarily seal off female JIC ports (e.g., idle ports of valve blocks, oil ports, tees) to prevent leakage and contamination. Male JIC plugs screw into female JIC ports.

Counterpart: End caps are used to seal male JIC ports (e.g., hose fitting ends), typically female threads with a 37° female taper.

Main types of JIC 37° flare fittings: Classification by port form (describes thread and taper orientation of fitting end)

Female JIC ports.

Description: Ports with female thread and internal 37° female taper sealing face.

To connect: with male JIC fitting ends (with 37° male taper) or male JIC plugs. When tightened, the male tapered face presses into the female tapered face to form a metal-to-metal line seal.

Common locations: manifolds, cylinders, pumps, motors, diverters, tee/elbow ports, nut ends of hose fittings.

Male JIC Ports.

Description: Port with male thread and 37° tapered sealing face.

Connection: Fits female JIC fitting ends (with 37° female taper) or female JIC end caps.

Common locations: end of straight/elbow/tee fittings, end of hard pipe (to be flared), core end of hose fittings.

Main types of JIC 37° flare fittings: Classification by installation method/connection object

Tube Fittings.

Description: Specially designed for connecting hard tubes. The fitting itself contains a JIC port (female or male) and the end of the hard pipe must be flared to a 37° flare using a special tool.

Connection Procedure: Insert the flared hard pipe into the fitting body and tighten the mating JIC nut (female thread with 37° female taper) onto the male JIC port of the fitting body. The inner taper of the nut presses the flared end of the tube against the outer taper of the fitting body to form a seal. (This is the core, standard application of the JIC fitting).

Hose Fitting Core.

DESCRIPTION: Fitting has a male JIC port (with a 37° male taper) on one end and a core (with a barbed or smooth surface, to be mated with the jacket nut and hose) on the other end for pressing into the bore of the hose.

Function: Serves as one end of a hose assembly with a JIC port for connection to a female JIC port in a system.

Hose Fitting Nut.

Description: Fitting has a female JIC port (with 37° female taper) on one end and a jacket nut (female) on the other end to fit over the hose, requiring a core.

Function: The other end of the hose assembly has a JIC port for connection to a male JIC port in the system.

Flanged Fittings/SAE Flanged Fittings.

Description: Although not strictly a “flare” joint, it is very common. It has a four-bolt flange with a flat seal in accordance with SAE J518 Code 61 (or Code 62) on one end and a standard JIC 37° flare connection (female or male) on the other.

Function: Used to connect JIC piping systems to equipment ports that utilize SAE flanges (e.g., pumps, motors, large diameter valve blocks). Seals with O-rings or flat gaskets on the flange faces.

Summary of Key Features of JIC 37° Flare Fittings

37° Tapered Seal.

This is the central identifying feature and sealing principle of JIC fittings. All types of seals rely on the metal-to-metal wire contact seal created by two precision-machined 37° tapers (one inner, one outer) when tightened.

Inch Threads.

JIC standards utilize inch uniform threads (UN/UNF) such as 1/4“ 20UNF, 3/8” 24UNF, 1/2“ 20UNF, 3/4” 16UNF, 1” 14UNF, etc.

Material.

Commonly used carbon steel (zinc plated, phosphated or cadmium plated to prevent rust), stainless steel (304, 316) and brass (low pressure or corrosive environments).

Standards.

Comply with SAE J514 standards for dimensions, tolerances, materials, testing, etc. Fittings conforming to the standard are interchangeable.

APPLICATIONS.

Widely used in industrial hydraulic, pneumatic (partial low pressure), lubrication and fuel systems that require medium to high pressure, reliable sealing and repeatable disassembly. Especially suitable for vibration and shock occasions.

Flare Requirements.

When used to connect hard pipe, the pipe end must be precisely flared to 37° using a special flaring tool, otherwise an effective seal cannot be formed.

Related Article:

Difference between jic and npt vs. bsp threads

JIC VS An Fittings, The Ultimate Guide

JIC vs SAE Hydraulic Fittings: Key Differences and Selection Guide

JIC 37° Flare (SAE J514) Size Chart

| Inch size | Dash size | Thread Size | Male Thread O.D. (in) | Female thread O.D (in) | ||

| 1⁄8 | -2 | 5⁄16 – 24 | 5⁄16 | 0.31 | 9⁄32 | 0.27 |

| 3⁄16 | -3 | 3⁄8 – 24 | 3⁄8 | 0.38 | 11⁄32 | 0.34 |

| 1⁄4 | -4 | 7⁄16 – 20 | 7⁄16 | 0.44 | 13⁄32 | 0.39 |

| 5⁄16 | -5 | 1⁄2 – 20 | 1⁄2 | 0.50 | 15⁄32 | 0.45 |

| 3⁄8 | -6 | 9⁄16 – 18 | 9⁄16 | 0.56 | 17⁄32 | 0.51 |

| 1⁄2 | -8 | 3⁄4 – 16 | 3⁄4 | 0.75 | 11⁄16 | 0.69 |

| 5⁄8 | -10 | 7⁄8 – 14 | 7⁄8 | 0.88 | 13⁄16 | 0.81 |

| 3⁄4 | -12 | 1 1⁄16 – 12 | 11⁄16 | 1.06 | 1 | 0.98 |

| 7⁄8 | -14 | 1 3⁄16 – 12 | 1 3⁄16 | 1.19 | 1 1⁄8 | 1.10 |

| 1 | -16 | 1 5⁄16-12 | 1 5⁄16 | 1.31 | 1 1⁄4 | 1.23 |

| 1 1⁄4 | -20 | 1 5⁄8 – 12 | 1 5⁄8 | 1.63 | 1 9⁄16 | 1.54 |

| 1 1⁄2 | -24 | 1 7⁄8 – 12 | 1 7⁄8 | 1.88 | 1 13⁄16 | 1.79 |

| 2 | -32 | 2 1⁄2 – 12 | 2 1⁄2 | 2.50 | 2 7⁄16 | 2.42 |

JIC 37° flare fitting key technical parameters

Sealing angle: Core feature, 37°.

Thread specification: Adoption of inch uniform thread (UN/UNF), common thread size:

| Tube OD (in.) | Common Designators | Fitting Nut Thread Size |

| 3/16” | 4 | 7/16”20 UNF |

| 1/4” | 5 | 1/2”20 UNF |

| 5/16” | 6 | 9/16”18 UNF |

| 3/8” | 6 | 9/16”18 UNF |

| 1/2” | 8 | 3/4”16 UNF |

| 5/8” | 10 | 7/8”14 UNF |

| 3/4” | 12 | 11/16”12 UN |

| 1” | 16 | 15/16”12 UN |

| 11/4” | 20 | 15/8”12 UN |

| 11/2” | 24 | 17/8”12 UN |

| 2” | 32 | 21/2”12 UN |

Pressure Rating: Depends on material, size and manufacturing process. Commonly used carbon steel fittings can operate at pressures of 5000 PSI (345 BAR) or more, stainless steel slightly less. Consult manufacturer’s specifications.

Temperature Range: Typically 65°F to +400°F (54°C to +204°C), depending on seal material and fluid.

Applicable Tubing: Specialized tubing for flared fittings (SAE J525) is required. Common materials include:

Carbon steel (e.g., SAE 1010, 1026)

Stainless steel (e.g., 304, 316)

Copper and copper alloys

Aluminum (application specific)

Materials: Fitting bodies and nuts are commonly made of carbon steel (zinc plated, phosphated or cadmium plated to prevent rust), stainless steel (304, 316) and brass.

JIC 37° Flare-Off Fittings Proper Selection Guide

- Confirm tube size: Measure the outside diameter (OD) of the tube to be connected accurately. 2.

- Determine the type of fitting: Select the corresponding type according to the needs of piping layout (straight through, turn, branch, plug, conversion, through the plate).

- Match thread size: Select the correct fitting nut thread size according to the pipe OD (common designation).

- Evaluate working conditions:

Working Pressure: The pressure rating of the selected fitting must be much higher than the maximum working pressure of the system, taking into account the safety factor.

Operating Temperature: Ensure that the fitting material and seal (if applicable) are compatible with the system temperature range.

Fluid Media: Ensure that the fitting material (carbon steel, stainless steel, brass) is compatible with hydraulic oil, lubricant, fuel oil, water, air or other media to prevent corrosion.

Vibration and environment: vibration environment need to ensure that the correct installation and support; harsh environments (corrosion, high temperature) consider stainless steel. 5. - Consider standards compatibility: If other standard fittings (e.g. NPT, SAE flange, BSPP) need to be connected, select the correct combination of gasket fittings.

JIC 37° Flare-Off Fittings Industry Applications

JIC 37° fittings are widely used because of their reliability and versatility:

Construction machinery: excavators, loaders, bulldozers, cranes (hydraulic cylinder, pump, valve block connection).

Agricultural machinery: tractor, harvester hydraulic system.

Industrial equipment: injection molding machines, presses, machine tools, hydraulic and pneumatic systems.

Transportation: trucks, buses (fuel, hydraulic, air brake systems), aerospace (some subsystems).

Oil & Gas: Oilfield equipment (non-high-pressure trunk lines), lubrication systems.

Marine & Offshore: deck machinery, engine auxiliary systems.

Power generation and energy: turbine lubrication, control systems.

Mobile hydraulics: hydraulic power units, tool connections.

Key steps in the installation of JIC 37° flare fittings

Correct installation is the key to a reliable seal, preventing leaks and failures!

- Cutting Tubing: Use a special tube cutter to ensure that the cut is straight, perpendicular to the tube axis, and free of burrs.

- Deburring: Thoroughly clean all burrs and sharp edges on the inside and outside of the pipe end (file, deburring tool). 3.

- Prepare to Flare: Place the fitting nut and sleeve (if used) on the tube in the correct orientation (nut threaded end facing out).

- Form flare: Use special 37° flare tool.

Clamp the tube in the tool chuck, making sure the tube end extends the required length (check tool instructions).

Center the 37° tapered punch on the end of the tube.

Apply even pressure to create a smooth, even, crack-free 37° flare in the end of the tube.

Check flare quality: Flare surface should be smooth, free of cracks and scratches, with an accurate angle (37°) and uniform thickness. - Assemble the connection:

Insert the flared tube into the fitting body.

Thread the fitting nut onto the male threads of the fitting body by hand, ensuring initial alignment.

Use a wrench to hold the fitting body in place (to prevent it from turning) and another wrench to tighten the fitting nut. - Tightening torque: critical!

Check the table of recommended torque values (based on size and material) provided by the manufacturer.

Following the “tighten, loosen, retighten” procedure will help to obtain a more consistent seal.

Avoid over-tightening! This can distort, crack, or damage the threads, causing leakage. - Pressure Test: Always pressure test all fittings for leaks after system installation or repair.

Conclusion

The choice of JIC 37° fittings depends on the layout of the line (straight, turn, branch), the type of equipment ports to be connected (female, male, flange), the size of the tubing, and whether the connection is to a hard or a soft hose. 37° flare fittings are an indispensable connecting element in hydraulics and fluid power systems thanks to their robust metal-to-metal sealing, proven industry standards, a wide range of types, and extensive scope of application. JIC 37° flare fittings are indispensable connecting elements in hydraulic and fluid power systems. A thorough understanding of standards, proper selection and installation techniques, and the ability to quickly diagnose and troubleshoot common problems are the keys to reliable, efficient, leak-free operation. Always give preference to high-quality products that meet SAE J514 standards, strictly follow the manufacturer’s installation guidelines and torque requirements, and perform regular system inspections and maintenance will maximize the performance and longevity of your JIC fittings. If you have additional questions about JIC 37° fittings, please contact one of our factory technical engineers, who will help you solve your selection problems free of charge.