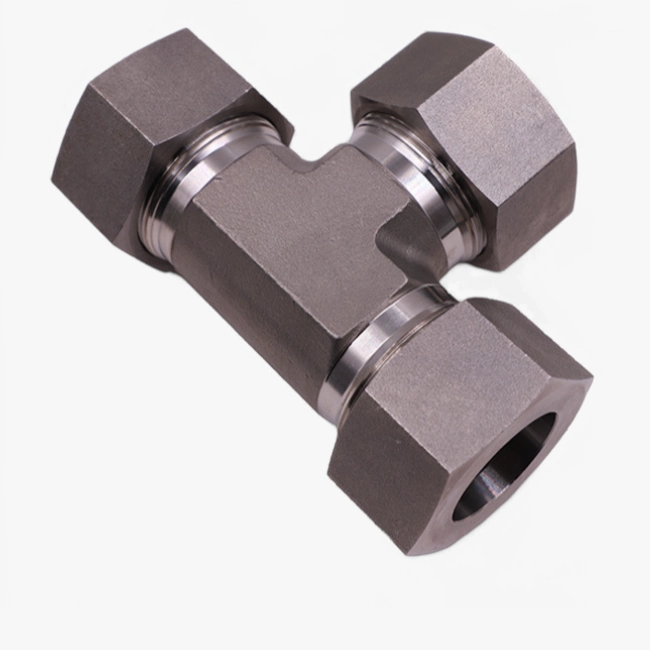

Different types of hydraulic tee fittings

Hydraulic tee fitting is a key component in hydraulic system for connecting, branching or changing the direction of fluid, which can split a hydraulic line into two (or merge two lines), while maintaining system sealing and pressure stability.

Its structure is usually T-shaped (an inlet connected to two outlets) or Y-shaped (two inlets connected to an outlet), can realize the hydraulic pipeline shunt, merge or bypass function.

It is widely used in engineering machinery, agricultural equipment, industrial hydraulic systems and other fields.

Hydraulic Tee Fitting Structure and Composition

- Main body: usually made of high-strength metal (e.g. carbon steel, stainless steel, brass), with internal design for fluid passage.

- Connection port: contains one inlet and two outlets (or opposite), with various forms of interface (such as threaded, flanged, ferrule type).

- sealing components: adopting O-ring, metal gasket or conical sealing structure to ensure no leakage under high pressure.

- Protective coatings: some of the joint surfaces are galvanized, phosphated or sprayed with anti-rust coating to adapt to the harsh environment.

Hydraulic tee fitting type

- Structure points:

T-type tee: three ports are distributed at right angles, suitable for space-constrained scenes.

Y-type tee: branch ports at an angle to reduce fluid resistance.

Equal/reduced diameter tee: the branch ports have the same or different diameters, suitable for different flow requirements. - Functionality:

Diverter Tee: Equally distributes fluid to two branches.

Priority Tee: Distribute the flow in proportion to the preset pressure (e.g. prioritize the supply to one branch).

Adjustable Tee: Controls branch flow or direction through a valve. - According to the connection method:

Threaded connection (such as NPT, BSPP, metric thread).

Flange connection: for high-pressure large-diameter pipeline.

Quick-change joints: support quick plugging and unplugging for easy maintenance.

- Predominantly material quality classification:

Carbon Steel: ASTM A105,20#, Q235, 16Mn, ASTM A350 LF1,LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42,F46,F48,F50,F52,F56,F60,F65,F70 etc.

Alloy steel: ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, St45.8/III, 35CrMoV, 45 CrMo, etc.

Stainless Steel: ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8, etc.

Hydraulic tee fitting application scenario:

Engineering machinery: excavator, crane hydraulic system in the pipeline branch.

Agricultural machinery: power distribution in the hydraulic suspension system of tractors.

Industrial hydraulic station: lubrication system or coolant flow control.

Aerospace: high-precision hydraulic circuit direction switching.

Hydraulic tee fitting procurement selection points

- Pressure level: need to match the maximum working pressure of the system (commonly 16-42MPa).

- material compatibility: according to the type of fluid (oil, water-based, corrosive media) to choose stainless steel or corrosion-resistant alloys.

- interface size: to ensure that with the existing piping specifications (such as 1/4 “-2”).

- temperature range: high temperature environment requires the use of heat-resistant sealing materials (such as Viton).

- Certification standards: in line with ISO 8434, SAE J514 and other international norms.

Hydraulic Tee Fittings Pricelist

| Descriptive | Material | Standard | prices | Delivery time |

| Swagelok Model Satinless Steel Compression Fittings Tee Tube Fittings | Stainless Steel | DIN、ANSI、GB、JIS | 0.5-9.9 USD/piece | 15-25 Days |

| Tee Carbon Steel Swagelok Standard Hydraulic Fittings | Medium Carbon Steel | DIN | 0.2-9.9 USD/piece | 15-25 Days |

| SAE Standard Carbon Steel Male Jic Tee Pipe Hydraulic Tee Fittings | Carbon Steel | SAE | 0.65 USD/piece | 15-25 Days |

| Hydraulic bite type tee fitting | Carbon Steel | DIN | 0.50 USD/piece | 15-25 Days |

| SAE Flareless Hydraulic Adaptor Tee Fitting | Carbon Steel | SAE | 0.55 USD/piece | 15-25 Days |

| Stainless Steel Tee Fitting Hydraulic Fitting with Gasket | Stainless Steel | DIN | 1.5-3.6 USD/piece | 15-25 Days |

| 1/2” NPT Male Tee Type Fitting SS316 Stainless Steel Hydraulic Tee Fitting | Stainless Steel | DIN | 5.0-15 USD/piece | 15-25 Days |

| 1/4 3/8 1/2 3/4 1 in. Hydraulic Fractional G Thread Female Tees | Carbon Steel | BSP/BSPT | 0.5-9.9 USD/piece | 15-25 Days |

| 1/2 stainless steel 316 reducer tee-type hydraulic fittings with double ferrules | Stainless Steel | DIN | 5.0-12 USD/piece | 15-25 Days |

Hydraulic tee fitting installation and maintenance

Installation steps:

- Clean the piping ports to avoid impurities.

- Use torque wrench to tighten according to the standard to prevent deformation caused by over-locking.

- Check whether the seals are intact and apply hydraulic sealant if necessary.

After-sales maintenance recommendations:

Regularly check the joints for leakage or corrosion.

Use original parts when replacing seals.

Relieve the pressure during system shutdown before disassembly to ensure safety.

Hydraulic tee fitting future development trend

- Lightweight: the use of aluminum alloy or composite materials to reduce weight.

- Intelligent: integrated pressure sensor real-time monitoring of flow and leakage. 3.

- environmental design: reduce harmful substances in sealing materials (such as lead-free copper).

- Modular: support for rapid assembly and customized branching solutions.

Summarize:

Hydraulic tee fittings are an important guarantee for the efficient operation of the hydraulic system, the selection needs to take into account the pressure, medium, environment and other factors, and follow the norms of installation and maintenance, in order to extend the service life and ensure system safety. Procurement for different types of hydraulic fittings, we provide high-quality hydraulic fittings to ensure that your hydraulic system to run in the best condition, want to know more about hydraulic fittings, please contact our technical staff, we will be free of charge for your procurement selection, to provide advice and guidance.