Common types of hydraulic fittings with O-rings

There are more types of hydraulic fittings with O-rings, which are mainly categorized according to the different sealing forms, structural designs and application scenarios.

The main types are:

O-ring face seal fittings (ORFS)

Characteristics: O-ring flat sealing design, suitable for high-pressure, vibration environment, with anti-torque, zero clearance installation and other advantages, reliable sealing performance.

Standard & Model:

Parker (PARKER) Seal-Lok series, in accordance with SAE J1453 and ISO 8434-3 standards, the size range of 1/4 inch to 2 inches, pressure resistance up to 9200 psi, suitable for hydraulic oil and gas transmission.

U.S. ORFS fittings, such as 1FG9-OG model, support customized material (carbon steel, stainless steel, etc.) and thread form, suitable for automotive, marine, construction machinery and other fields.

ferrule type o-ring hydraulic fittings

Characteristics: Connected with pipeline through ferrule, combined with O-ring to realize sealing, easy installation and high pressure resistance.

Typical products:

TN419 adjustable right angle fittings, in accordance with DIN2353 standard, made of medium carbon steel, applicable pressure 16-63 MPa, temperature range -40 ℃ to +120 ℃, widely used in hydraulic pipeline connection.

Types of O-ring seals in transition fittings

Metric male O-ring flat seal fittings: such as 90°, 45° elbows, plugs, over-board fittings, etc., applicable to different connection requirements of hydraulic systems.

Heavy series fittings: such as metric male O-ring flat seal heavy series, with more robust design, suitable for high load scenarios.

Other special structure fittings with O-rings

Adjustable Column End Fittings: e.g. 45° or 90° adjustable design, easy to adjust the installation angle while maintaining sealing.

Welded or flared fittings: Some brands provide different connection forms such as welded and flared, combined with O-rings to realize sealing, suitable for non-standard or special piping needs.

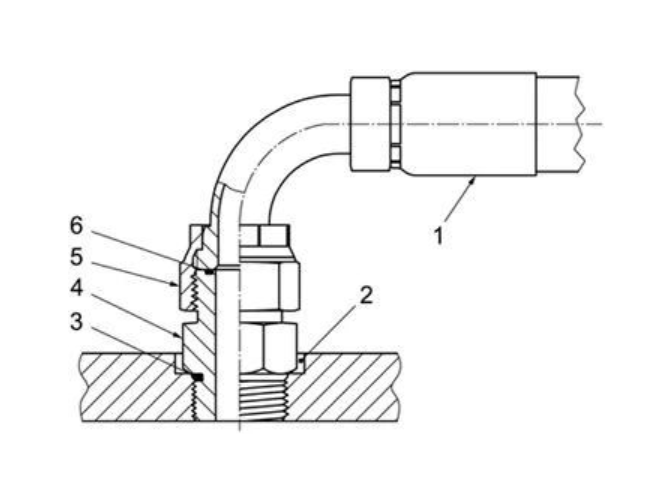

Pictures of common hydraulic fittings with O-rings, as well as application and installation.

1.Hose Connector

2.Oil port

3.O-ring

4.Fitting

5.Nut

6.O-ring

When the nut 5 is screwed to the outer thread of the fitting body, with the increase of tightening torque, the hose coupling and the end face of the fitting body (piece 4) come into contact with each other and are pressed together, and the O-ring on the end face of the fitting 4 produces elastic deformation, which is in full contact with the end faces of the piece 6 and the piece 4 and produces pressure, and serves as sealing effect.

The installation process requires special attention, check the sealing ring before installation.

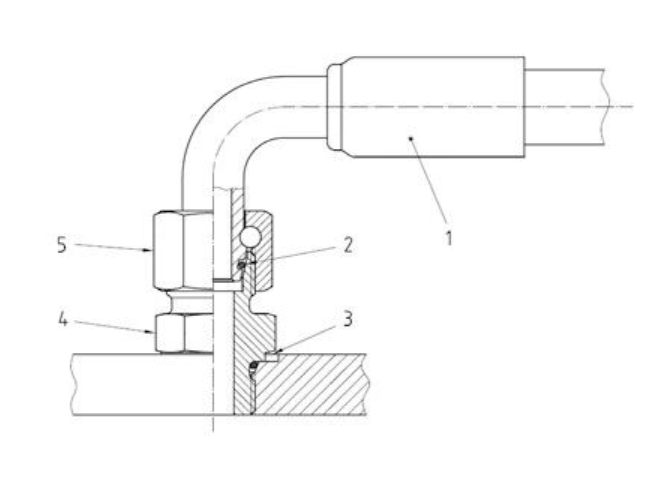

1.Hose fittings

2.O-ring

3.Fitting

4.Nut

When the nut 5 and the fitting body (piece 4) of the external threads screwed together, with the increase of tightening torque, the hose connector outer cone and the connector body (piece 4) between the inner cone contact and compression, the O-ring of the outer cone of the hose connector 1 to produce elastic deformation, and the pieces of the 5 and pieces of the 4 cone surface to fully contact and generate a greater pressure, to play the role of the sealing, due to the leverage of the taper surface, the pressure between the taper surface is greater, the sealing effect of theoretical Better. The installation process requires special attention, check the sealing ring before installation.

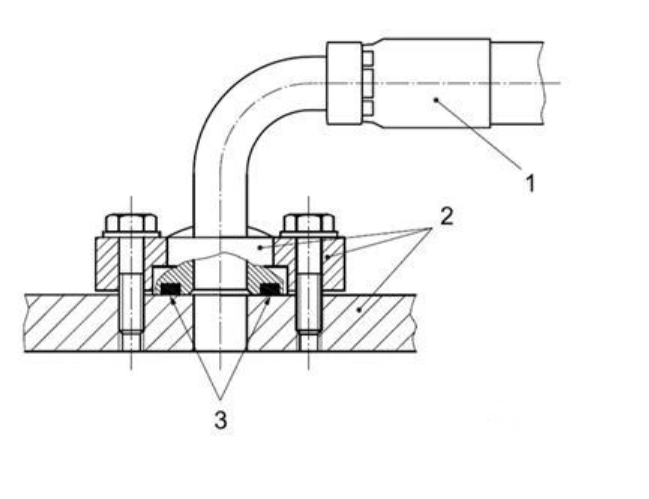

1.Hose fittings

2.Oil port, flange head, flange pressure plate

3.O-ring

The flange head of the hose coupling is pressed on the oil port by the flange pressure plate, when the bolt tightening torque increases, the bolt generates a great preload, the bolt preload is passed through the flange pressure plate, and the flange head is tightly pressed on the oil port, and the O-ring on the head of the flange ( 3) is deformed by the pressure, and the flange head end face of the hose coupling (1) is in full contact with the surface of the oil port and the pressure generated, which plays the role of sealing, due to the use of high-strength bolts, the pressure between contact surfaces is very high, and the pressure between contact surfaces is very high. Due to the use of high-strength bolts, the pressure between the contact surfaces is very high, and the sealing effect is theoretically very good.

Conclusion:

Industry applications: including construction machinery, military equipment, ships, petrochemical, automobile manufacturing, etc.

Selection key: according to the working pressure, media type (oil, water, gas), temperature range and thread standard (metric, American, British) to choose the corresponding model.